close

Choose Your Site

Global

Social Media

Views: 0 Author: Site Editor Publish Time: 2025-09-17 Origin: Site

OAP mirrors are very important in advanced optical systems. They help focus light very well. Engineers pick, set up, and use these mirrors to make images clearer. They also help get a sharp focus. The special design lets people control how light moves in the system. The shape and place of each mirror are very important. Putting the elliptical aperture center and off-axis distance in the right spot helps lower wavefront errors. This gives better pictures. Good clocking and alignment make sure the system works well every time.

OAP mirrors help focus light in advanced optical systems. They make images clearer and lower wavefront errors.

Picking the right OAP mirror means looking at things like focal length, surface quality, and coating type. This helps the mirror work its best.

It is important to install and align OAP mirrors the right way. Engineers should follow certain steps to stop mistakes and keep light paths correct.

Cleaning and checking OAP mirrors often can stop problems like dust and misalignment. This helps keep images clear.

OAP mirrors are used in many fields, like aerospace, medical devices, and spectroscopy. They help these areas work better and faster.

Image Source: pexels

Choosing OAP mirrors starts with knowing what matters most. Engineers check things like focal length, diameter, coating, and how smooth the surface is. Each part changes how the mirror works in the system.

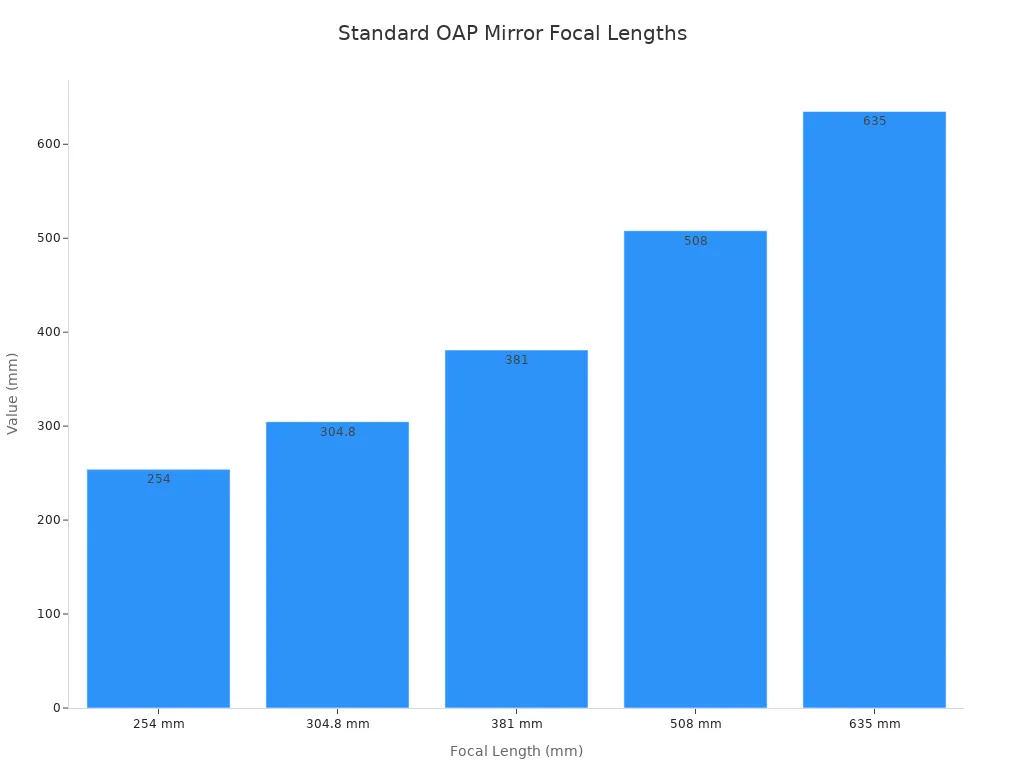

| Standard Focal Lengths (mm) |

|---|

| 254 |

| 381 |

| 508 |

| 635 |

| 304.8 |

Surface quality is very important for clear results. Engineers use PV and RMS numbers to check how smooth the mirror is. A PV number less than λ/2 means the mirror is very good. Some OAP mirrors have PV numbers from λ/8 to λ/4. This helps stop light from spreading out and keeps images clear. If the surface is smoother, there is less unwanted light scatter.

The coating on the mirror matters for different kinds of light. Here is a table that shows common coatings and what they do:

| Coating Type | Key Characteristics |

|---|---|

| Protected Silver | Reflects most light; needs a cover to protect it. |

| Protected Gold | Works well in tough places; best for near-infrared; needs a cover. |

| Protected Aluminum | Used a lot; good for visible light; can add layers to work better. |

| Multi-layer Dielectric | Absorbs little light; strong against lasers; can be made for special jobs. |

What the mirror is made of changes price and how well it works. Engineers pick metals, glass, or ceramics like SiC to get the right mix. Mirrors without a wedge can cost less if they have big angles or openings.

To match OAP mirrors to a system, engineers look at shape, offsets, and how things line up. Shape means sag and off-axis angle. They also check the beam’s shape and how it fits the mirror.

Tip: Picking good materials and having easy ways to line things up makes the system work better and easier to set up.

New ways to make OAP mirrors help them last longer and weigh less. New coatings, like dielectric and protected gold, make them reflect more light and are easier to clean. Better computer tools and new materials help engineers design better mirrors.

Rules for using OAP mirrors change for each job. Telescopes need mirrors with exact shapes and coatings that reflect a lot of light. Cameras need mirrors that show colors right and make sharp pictures. Outdoor systems need strong materials and covers to protect them.

| Application Domain | Key Requirements | Material Types | Coating Options |

|---|---|---|---|

| Telescopes | Stop image problems | Aluminum, Silver | Coatings that reflect well |

| Cameras | Show colors right and sharp pictures | Many types | Special coatings |

| Outdoor Environments | Stay strong and safe outside | Tough materials | Protective coatings |

How you place and turn the mirrors is very important. Engineers do these steps:

Open the Lens Data Editor and pick the right surfaces.

Use the Tilt/Decenter Elements tool.

Make ‘Tilt About Z’ something you can change.

Move the mirror so the beam goes straight along the bench.

Add a rule to keep the Y Direction Cosine at zero.

Make sure the parabola’s Tilt About Z is less than 180 degrees.

Change the design to get the best score.

Use the Hammer Optimizer if you need extra help.

Doing these steps helps OAP mirrors work their best in advanced optical systems.

Engineers use a simple process to install OAP mirrors. First, they get the workspace ready and collect all tools. Clean gloves and special wipes keep the mirror clean. This stops dust and fingerprints from getting on the surface. The mounting bracket must match the mirror’s size and shape.

Here is an easy guide for mounting:

Put the OAP mirror on a soft, clean spot.

Attach the bracket gently so you do not scratch it.

Use screws or clamps to hold the mirror, but do not make them too tight.

Make sure the mirror sits flat and does not lean.

Use a level to check if the mirror lines up with the bench.

Look for marks or dust before you start alignment.

Tip: Hold mirrors by the edges only. Touching the shiny part can leave marks and make them work worse.

Engineers think about other things when putting in mirrors. Surface roughness changes how much light scatters. Most OAP mirrors have roughness less than 50Å or 100Å RMS. The coating type changes how the mirror works in different setups. The beam must go straight along the optical axis. This helps stop comatic aberration and keeps images sharp.

| Factor | Description |

|---|---|

| Surface Roughness | Changes how light scatters; usually less than 50Å or 100Å RMS for OAPs. |

| Coating Options | Many coatings change how well the mirror works. |

| Incident Beam Alignment | Beam must be straight with the optical axis to stop comatic aberration. |

Good alignment helps OAP mirrors work better. Engineers use tools like crosshairs, lasers, and alignment telescopes. They move the mirror until the reflected light matches the system’s optical axis.

Steps for alignment are:

Shine a straight light onto the mirror.

Move the mirror so the reflected beam hits the target.

Change the space between the mirror and the plane mirror to make the path shorter.

Look for errors in the reflected light. Make small changes to fix these problems.

Check that the focused light makes a straight beam after bouncing off the mirror.

Mistakes can happen if engineers hurry or skip steps. The table shows common errors and how to fix them:

| Common Alignment Errors | Solutions |

|---|---|

| Wrong space between the plane mirror and OAP | Keep the space short to make the path back to the OAP smaller. |

| Errors in the reflected light | Make careful changes to fix errors and center the light on the PSM crosshair. |

| Focused light not lined up | Change the space between the light source and the OAP to get a straight beam from the OAP. |

Note: Engineers should always check alignment after each change. Small mistakes can make images blurry or hard to focus.

When engineers align OAP mirrors well, images get much better. The mirrors make perfect focus points for straight light beams. Good alignment keeps the light straight, which helps meet tough needs in advanced optical systems.

| Key Element | Description |

|---|---|

| Focus Points | OAP mirrors make perfect focus points for straight light beams. |

| Light Collimation | Good alignment keeps light beams straight. |

| Performance Requirements | OAP mirrors meet strict needs in advanced optical systems. |

Engineers who follow these steps and fix mistakes help their systems work their best. Careful setup and alignment give clear images and good results.

OAP mirrors help make images sharp. But some problems can still happen. Engineers see a few main types of aberrations:

Spherical aberration: OAP mirrors do not have this problem.

Comatic aberration: This happens if the light beam is not parallel.

To fix these problems, engineers keep the light beam straight. They make sure the beam stays parallel to the optical axis. This helps stop comatic aberration and keeps images clear. Careful alignment and checking often help a lot. When the mirror is in the right spot, the system works better. Images look sharper too.

Engineers use different ways to help OAP mirrors work well. They look at how the mirror mount is made. A good mount holds the mirror steady. It does not put stress on the mirror. In strong systems, even small shape mistakes or glue stress can cause trouble. Engineers pick the right glue pad size and thickness. This helps lower heat stress and keeps the mirror safe. If the mount works well, the mirror stays in place. The system runs smoothly.

If problems show up, engineers check for dust or loose mounts. They clean the mirror with special wipes. They fix the mount if needed. They also look for stress or bending in the mirror. Quick fixes are tightening screws gently or moving the beam. Checking often and careful handling stop most problems.

Tip: Engineers should always wear clean gloves. They should hold mirrors by the edges to avoid new problems.

Image Source: pexels

OAP mirrors are used in many advanced optical setups. Engineers put these mirrors in target simulators and collimators. They also use them in MTF measuring systems. Each job needs the mirror to focus and direct light very well.

The table below shows where OAP mirrors help make things better:

| Application Area | Description |

|---|---|

| Research | Used in experiments for careful measurements. |

| Astronomy | Focuses light from faraway space objects. |

| Quantum Optics | Changes light at the quantum level. |

| Experimental Labs | Helps with different optical experiments. |

| Photonics | Makes photonic devices. |

| Environmental Sensing | Finds changes in the environment using light. |

| Advanced Manufacturing | Used in laser cutting and making things. |

| AR/VR Displays | Improves visuals in AR and VR. |

Engineers pick OAP mirrors for MTF measuring systems a lot. These systems check how well a device shows details. The mirrors help make the system smaller and lighter. They also help save money. The table below shows the main good points:

| Application | Key Advantages |

|---|---|

| MTF measuring systems | Make systems smaller |

| MTF measuring systems | Make systems lighter |

| MTF measuring systems | Save money |

| MTF measuring systems | Make systems work better and sell more |

OAP mirrors work in many different industries. Engineers use them in aerospace for telescopes and beam steering. Medical devices need them for pictures and surgery tools. Spectroscopy uses these mirrors to collect focused light for research and work. Laser systems use OAP mirrors for strong focusing and shaping beams. Industrial and R&D teams use them in test gear and new designs.

Aerospace: Telescope optics, beam steering, laser communication.

Medical Devices: Imaging systems, surgery optics, diagnostic tools.

Spectroscopy: UV, visible, IR setups, fluorescence, Raman spectroscopy.

Laser Systems: Focusing, collimation, cutting, welding.

Industrial and R&D: Test gear, science experiments, engineering prototypes.

Note: OAP mirrors fit many optical setups. Their design helps engineers fix problems in science, industry, and technology.

Good OAP mirror setup begins with a strong leader. The team picks someone to lead and give jobs to others. They split the work into smaller parts and use tools to keep data safe. Checking for risks early and talking often helps stop problems. Engineers who do these steps make their systems better. They get clearer images and better results. These ways help anyone make advanced optical setups easier and work better.

OAP means Off-Axis Parabolic. Engineers use these mirrors to focus light. They also direct light without blocking the center like regular mirrors.

OAP mirrors do not make colors bend wrong. They reflect all colors the same way. Lenses can bend colors in different ways. This can make pictures blurry.

Engineers wear clean gloves and use special wipes. They do not touch the shiny part. They blow off dust with air or use a soft brush.

Yes, OAP mirrors work well with laser beams. They focus or make light straight very accurately. Many engineers use them in laser setups.

If an OAP mirror is not lined up right, images can get blurry. Light can also scatter. Engineers check the alignment often to keep things working well.