close

Choose Your Site

Global

Social Media

Views: 0 Author: Site Editor Publish Time: 2025-09-11 Origin: Site

Manufacturers make aspheric lenses from different materials. These include glass, plastic, and crystalline types. Each material has special benefits for certain uses. The table below shows how much each material is used:

| Material Type | Market Share (%) | Growth Rate |

|---|---|---|

| Glass Aspheric | 33.0 | Highest due to strength |

| Plastic Aspheric | N/A | Fastest growth from 2025-2032 |

The material you choose changes how well aspheric lenses work. Aspheric lenses help make images clearer. They also lower distortions and fit many needs.

Aspheric lenses are made from glass, plastic, or crystalline. Each material works best for certain jobs.

Glass aspheric lenses are tough and give sharp images. They are good for medical tools and cameras.

Plastic aspheric lenses are light and not expensive. They work well in phones and projectors.

Crystalline aspheric lenses are great for infrared and thermal imaging. They are used in science and military work.

You should pick the lens material that fits your project. Think about cost, strength, and how clear the image is.

Image Source: unsplash

Glass is a common material for aspheric lenses. People pick glass because it lasts long and bends light well. These features help aspheric lenses work better and fix image problems. Many glass aspheric lenses use optical glass from brands like Schott, Hoya, and Ohara. Some special uses need fused silica or low-temperature optical glass. The table below shows what makes glass and plastic different:

| Material | Characteristics |

|---|---|

| Glass | Durable, high index of refraction |

| Plastic | Lighter, flexible, less expensive |

Glass aspheric lenses are strong and do not scratch easily. They work well in places with heat or chemicals. The shape of glass lenses helps fix mistakes in images.

Plastic aspheric lenses bend easily and cost less. Makers use many kinds of optical plastics, such as:

Polymethyl Methacrylate (PMMA)

Polystyrene (PS)

Polycarbonate (PC)

Allyl Diglycol Carbonate (ADC)

Plastic lenses are lighter than glass ones. They weigh about half as much as glass. This makes them simple to use. Plastic aspheric lenses can handle hits almost ten times better than glass. They are much cheaper to make, sometimes only one-tenth the price of glass. The refractive index of plastics is between 1.42 and 1.69, which is less than glass. These facts make plastic aspheric lenses good for light gadgets and electronics.

Crystalline materials give aspheric lenses special abilities. Makers shape these materials by diamond turning, grinding, or molding. Some common crystalline materials are germanium (Ge), silicon (Si), zinc selenide (ZnSe), and zinc sulfide (ZnS). These materials are used in infrared and thermal imaging aspheric lenses. The table below shows how different ways of making lenses use crystalline and other materials:

| Manufacturing Process | Materials Used |

|---|---|

| Diamond Turning | Infrared, Silicon, Zinc Selenide, Zinc Sulfide, Plastics |

| Grinding and Polishing | Optical glass, Fused Silica, Plastics, Ge, Si, ZnSe, ZnS |

| Precision Glass Molding | Low Temperature Optical Glass, Plastics |

| Injection Molding | Low Temperature Optical Glass, Plastics |

Crystalline aspheric lenses let lots of light through certain wavelengths. They help make advanced lenses for science and industry.

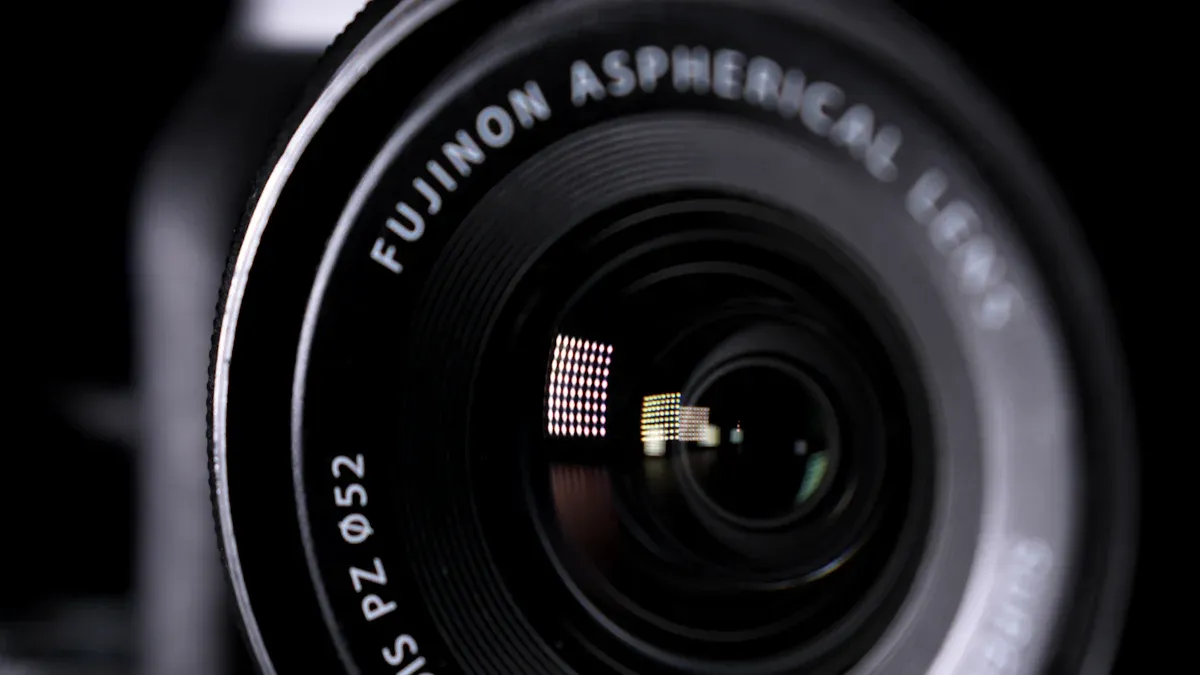

Image Source: pexels

Glass aspheric lenses are strong and work well with light. They are usually about 7.20 mm wide. The center is close to 4.47 mm thick. The clear part is 3.33 mm wide. This lets light go through the lens. The focal length is 6.50 mm. The numerical aperture is 0.42. These lenses work best from 800 to 1200 nm. Most have a BBAR coating. This coating helps stop reflections. It also makes the lens work better. The surface quality is 80-60. This means the lens stays smooth and clear. The f-number is 0.9. This helps the lens gather more light. These lenses follow RoHS safety rules.

| Property | Value |

|---|---|

| Diameter (mm) | 7.20 ±0.025 |

| Clear Aperture CA (mm) | 3.33 |

| Center Thickness CT (mm) | 4.47 |

| Effective Focal Length EFL (mm) | 6.50 |

| Numerical Aperture NA | 0.42 |

| Wavelength Range (nm) | 800 - 1200 |

| Coating | BBAR (800-1200) |

| Surface Quality | 80-60 |

| f/# | 0.9 |

| Regulatory Compliance (RoHS) | Compliant |

Glass aspheric lenses have good and bad sides. They fix spherical aberrations. This makes images look better. These lenses help make optical systems smaller and lighter. They give better focus and more accuracy. But glass aspheric lenses can break easily. They need careful alignment. Making these lenses is hard. Sometimes, the light area is smaller than other lens types.

| Advantages of Aspheric Lenses | Disadvantages of Aspheric Lenses |

|---|---|

| Correction of Spherical Aberrations | Complex Design and Manufacturing Process |

| Improved Image Quality | Fragility |

| Reduced Size and Weight of Systems | Alignment and Tolerance Requirements |

| Reduced Chromatic Aberrations | Limited Availability |

| Increased Accuracy and Consistency | Smaller Light Area |

Tip: Use glass aspheric lenses when you need sharp images and high precision.

Many industries use glass aspheric lenses for their strong performance. Smartphone cameras use these lenses for better pictures. Cars use them in driver-assistance systems and head-up displays. This helps keep drivers safe. Medical tools use these lenses for clear images. Defense systems use them in night vision and thermal imaging. These lenses help in many jobs that need good image quality and reliable correction.

Plastic aspheric lenses are light and easy to make. Makers use materials like PMMA and polycarbonate. These lenses are made by molding, which saves money. They weigh less than glass lenses. This makes them simple to use in many devices. But plastic aspheric lenses do not handle heat well. They also bend more under pressure, so they may not work in tough places.

Cost less than glass aspheric lenses

Light weight makes them easy to use

Molding helps make many lenses fast

Do not handle heat as well as glass

Bend more under pressure

Note: Plastic aspheric lenses often need coatings to work better in hard conditions.

Plastic aspheric lenses have many good points. They are cheaper and lighter than glass lenses. Molding lets makers create many shapes quickly. These lenses help fix image problems in cameras and other tools. New plastics make these lenses clearer and stronger.

| Pros | Cons |

|---|---|

| Cheap | Do not handle heat well |

| Light | Bend more under pressure |

| Easy to make many at once | Scratch easier |

| Fix image problems | May need coatings to last longer |

| Make images better | Not good for high-pressure places |

Plastic aspheric lenses are used in many things. Cameras use them for better pictures and smaller size. Laser tools use them to focus and shape beams. Medical tools, like endoscopes and eye lenses, use them for clear images. Science tools, such as telescopes and spectrometers, use them because they are light and work well. Projectors and VR headsets use plastic aspheric lenses for sharp, bright images.

Cameras and imaging tools

Laser pointers and cutting machines

Medical endoscopes and eye lenses

Telescopes and spectrometers

Projectors and VR/AR displays

Plastic aspheric lenses are popular because they are cheap, light, and work well. These features make them a good choice for many new devices.

Crystalline aspheric lenses use materials like germanium, silicon, zinc selenide, and zinc sulfide. The lens surface changes shape across the lens. This helps fix image problems and makes pictures clearer. These lenses let more light through certain wavelengths. That is why they work well for infrared and thermal imaging. Aspheric lenses need fewer parts to focus sharply. They are often thinner and lighter than regular spherical lenses. Their surfaces help fix mistakes in images that happen away from the center. This lets more light in and makes the lens work better. Scientists and engineers pick crystalline aspheric lenses for their accuracy and strong performance.

Crystalline aspheric lenses have good and bad sides. The table below shows the main points:

| Pros | Cons |

|---|---|

| Improved image quality | Higher cost |

| Reduced dysphotopsia | Need for additional measurements |

| Better contrast sensitivity in low light | Performance differences may be negligible for average patients |

These lenses fix spherical aberration and make images sharper. They give clear pictures even when it is bright. The lenses look nice because they are thin and light. But the smaller light area can make the edges blurry. Some people may see objects near their eyes sticking out. Crystalline aspheric lenses cost more than other types. They may need extra checks to fit right.

Crystalline aspheric lenses are used for advanced jobs. Scientists use them in infrared cameras and thermal imaging tools. Engineers use them for precise optical systems in labs and factories. Doctors use these lenses in medical machines that need clear images and good correction. Military and space technology also use crystalline aspheric lenses for top performance. Many makers choose these lenses for better image quality and less weight. Using fewer lenses helps make devices smaller and simpler. Crystalline aspheric lenses are important in modern optical tools.

Aspheric lenses work differently based on what they are made of. Glass aspheric lenses are best for very accurate systems. They have a high index of refraction and are tough. These lenses fix image problems and make pictures look better in hard places. Plastic aspheric lenses are lighter and bend more. They are used in things like phones and cameras. The shape of aspheric lenses helps stop image mistakes and makes devices work better. Crystalline aspheric lenses have special optical features. They are great for infrared and thermal imaging. Each lens material helps make images clearer and fixes image errors.

Glass aspheric lenses: Very accurate, fix image problems well, good for tough optical systems.

Plastic aspheric lenses: Light, bendy, good for small devices, nice for daily use.

Crystalline aspheric lenses: Special optical features, best for science and industry imaging.

Tip: Pick glass aspheric lenses if you want the best performance in pro equipment.

How long aspheric lenses last depends on the material. Glass lenses can handle heat and chemicals but break easier than plastic. Plastic aspheric lenses do not break as easily and are lighter. But they scratch and get damaged by chemicals more than glass. Crystalline lenses have great optical features but cost more and are hard to find in big sizes. Things like temperature and wetness change how each lens works. Glass lenses stay steady when the weather changes. Plastic lenses can get worse in sunlight and may not stay clear. Crystalline lenses keep their features but need gentle care.

| Material | Advantages | Limitations |

|---|---|---|

| Glass | Clear images, handles heat, resists chemicals | Heavy, breaks easier than plastic |

| Plastic | Cheap, light, does not break easily | Changes with heat, not good with chemicals |

| Crystals | Best optical features | Expensive, hard to get in big sizes |

Price is important when picking aspheric lenses. Plastic aspheric lenses are the cheapest to make. Factories can mold them fast and make lots at once. Glass aspheric lenses cost more because they need careful shaping and polishing. Crystalline aspheric lenses are the most expensive. Their special features and low supply make them cost more. What the lens is made of changes how much the whole device costs.

Plastic aspheric lenses: Cheapest, good for making many at once.

Glass aspheric lenses: Cost more, best for pro and science use.

Crystalline aspheric lenses: Most costly, used for special jobs.

Each aspheric lens material is good for different things. Glass aspheric lenses are used in pro cameras, medical tools, and car systems. They last long and give clear images for important jobs. Plastic aspheric lenses are found in electronics, toys, and light gadgets. They are light and cheap, so people use them every day. Crystalline aspheric lenses are used in science, infrared cameras, and military tech. Their special features help in these fields.

| Property | Plastic Lenses | Glass Lenses |

|---|---|---|

| Material Weight | Light and comfy | Heavy and less comfy |

| Durability | Does not break easily | Breaks if hit hard |

| Optical Clarity | Not as clear as glass | Very clear, little distortion |

The place where the lens is used also matters. Glass lenses handle heat and wetness better than plastic. Plastic lenses may not work well in tough places. Crystalline lenses keep working well but must be handled with care.

Note: Pick the lens material based on what the device does, where it will be used, and how much you want to spend.

Picking the right material for aspheric lenses is important. Many things affect how well the lens works. The table below lists the main things to think about:

| Factor | Description |

|---|---|

| Wavelength Requirements | The specific wavelengths the lens will be used for. |

| Manufacturing Cost | The cost associated with producing the lens material. |

| Manufacturing Techniques | The methods used to create the lens, impacting quality. |

| Performance Requirements | The optical performance needed for the application. |

| Development Cost | The costs involved in developing the lens for production. |

| Sample Cost | The cost of producing initial samples for testing. |

| Production Part Cost | The cost of producing the final lens in bulk. |

| Project Timeline | The time frame for completing the project. |

Engineers check wavelength needs first. Some aspheric lenses must work with visible light. Others need to handle infrared or ultraviolet light. The material must match the light type for best results.

Manufacturing cost and development cost are very important for big projects. Plastic aspheric lenses are common in cheap products like phones. They are light and do not cost much. Companies can make lots of plastic lenses fast. This helps lower the price for new technology. Better ways to make plastic lenses have made them stronger and clearer.

Doctors and scientists often use glass aspheric lenses. These lenses give clearer images and stay stable. Glass lenses are good for jobs that need high accuracy, like telescopes. Electronics makers usually pick plastic or mixed lenses to save money and still work well.

How you make the lens changes its quality. Diamond turning, grinding, and molding all give different results. Smooth surfaces help light go through and stop scattering. Special coatings can make lenses work better by cutting glare and reflection. Anti-reflective coatings help laser systems and screens work better.

Rules are important for medical and space jobs. For example, ISO 13485 gives rules for making medical devices. FDA 21 CFR Part 820 makes sure things are made well in the US. CE Marking is needed for things sold in Europe. These rules make sure aspheric lenses are safe and work right.

Tip: Always look at the project timeline and sample cost before picking a lens material. If you need lenses fast, plastic is a good choice. If you have more time, glass or crystalline may be better.

What you use the aspheric lens for helps pick the material. Each job has special needs that change which lens is best.

Laser systems need lenses that can handle strong energy and certain light types. Fused silica and S-LAH64 are good for these jobs. How you make the lens also matters. Diamond turning and precision molding help make very accurate lenses for lasers.

Medical tools and science machines need very exact aspheric lenses. Glass materials give the best image quality and stay steady in different places. These lenses help doctors and scientists see clearly and get good results.

Cameras and VR headsets often use plastic aspheric lenses. These lenses are light and do not break easily. Companies can make many plastic lenses quickly, so they cost less. Wearable devices use plastic lenses because they are light and strong.

The table below shows which materials are best for each job:

| Application Type | Recommended Materials | Quality Levels |

|---|---|---|

| High-Precision | S-LAH64, Fused Silica | Precision (RMSi < 0.5 µm), Ultra (RMSi < 0.1 µm) |

| Cost-Sensitive | N-BK7 | BeamTuning (RMSi < 0.02 µm) |

Aspheric lenses have changed how we use optics. Their special shapes fix image problems better than normal lenses. Smooth finishes and coatings help make images clearer and cut down on glare.

Rules also help pick the right material. Medical and space projects must follow strict rules to keep people safe and make sure things work. ISO 13485, FDA 21 CFR Part 820, and CE Marking are common rules for these jobs.

Note: Pick the lens material that fits the job. Glass or crystalline lenses are best for high-precision work. Plastic lenses are good for projects that need to save money.

Aspheric lenses are made from different materials. Each material helps lenses work better and fix image problems. Glass aspheric lenses are strong and accurate. Plastic aspheric lenses are light and save money. Crystalline aspheric lenses are used for special jobs. The table below shows what experts suggest for each use:

| Application | Recommended Materials |

|---|---|

| Laser Systems | Precision molded aspheric lenses in glass and plastic substrates |

| Imaging Devices (Cameras, Microscopes) | Aspheric lenses for improved resolution and sharpness |

Experts say you should think about a few things when picking aspheric lenses. The material you choose changes how the lens works in different places. You should look at the size, how far the lens focuses, how much light it lets in, how smooth the surface is, and if it has coatings.

Picking the best aspheric lens material helps make images clearer and fixes mistakes for every job.

Makers use glass, plastic, and crystalline materials for aspheric lenses. Each material works in its own way. Some give better image quality. Others help fix optical mistakes. The material you pick changes how well the lens works.

The lens material changes how images look. Glass makes pictures clearer and fixes more errors. Plastic is lighter but not as exact as glass. Crystalline materials help with special jobs, like seeing infrared light.

Aspheric lenses have a special shape. This shape bends light in a better way. It helps fix image mistakes. Regular lenses cannot fix errors as well. Aspheric lenses use careful designs to make images sharper.

Crystalline aspheric lenses are used for infrared and thermal imaging. Scientists and engineers use them for special tools. These materials let certain light waves pass through. This helps the lens work better for special jobs.

Plastic aspheric lenses are easy to make and fix some errors. They are not as exact as glass lenses. Plastic is good for light devices. But it may not make images as clear for hard jobs.