close

Choose Your Site

Global

Social Media

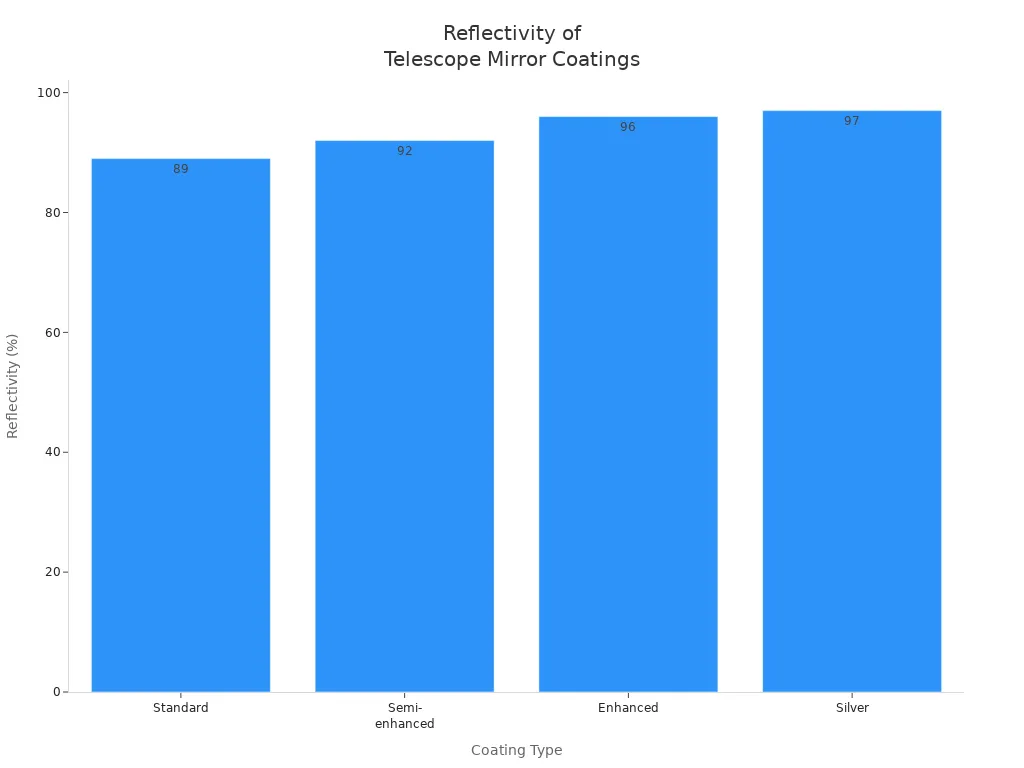

Coating a telescope mirror involves applying a thin, shiny layer to the main mirror. This coating telescope mirror enhances its ability to reflect more light, resulting in brighter and clearer images. The type of coating used can significantly affect the mirror’s performance and longevity. A standard coated mirror reflects approximately 89% of light, while enhanced coatings can achieve reflectivity of up to 97%.

| Coating Type | Reflectivity Percentage |

|---|---|

| Standard | 89% |

| Semi-enhanced | 92% |

| Enhanced | 96% |

| Silver | 97% |

Additionally, protective coatings play a crucial role in safeguarding the mirror from rust and temperature fluctuations. These benefits ensure that telescope images remain sharp and clear over time.

Coating a telescope mirror helps it reflect more light. This makes images look brighter and clearer. A good coating can reflect up to 97% of light.

You need to clean and care for the mirror often. This keeps the coating safe. Use distilled water and mild soap to stop scratches.

There are different coating types, like aluminum and silver. Each type reflects light in its own way. Pick a coating that fits your needs and telescope.

Protective overcoats are very important. They stop rust and scratches from hurting the mirror. Overcoats help the coating last longer.

Check your mirror for dull spots or tiny holes. These are signs of wear. You may need to recoat the mirror to keep it working well.

Image Source: pexels

Coating telescope mirror helps the telescope gather and bounce back more light. The main reason for coating is to make the mirror reflect as much light as possible. This lets astronomers see faint stars and faraway galaxies better. A mirror with a good coating reflects almost all the light that hits it. This makes the telescope show brighter and clearer pictures.

“If we add many layers of different materials, each layer helps the mirror reflect more light. This can make mirrors almost 99.999 percent reflective.”

A mirror with a strong coating will last longer. The coating keeps the glass safe from water, dust, and scratches. It also stops the mirror from rusting or getting dull. Coatings that reflect a lot of light help astronomers look at very dim things. Every bit of light is important when looking at space.

“Coatings that reflect more light are worth the extra cost. They help a lot when looking at very dim objects with big telescopes.”

The process of coating telescope mirror uses special tools and careful steps. First, workers take off any old coating from the mirror. They use special chemicals to remove the old layer. Then, they wash the mirror with clean water to make sure it is spotless.

Remove the old coating with ferric chloride

Wash the mirror with distilled water

Put on a new aluminum or silver coating

Add a layer to stop tarnish and protect the mirror

Dry the mirror with a hair dryer or air pump

Make sure to safely get rid of chemical waste

Next, workers use vacuum machines. They move the mirror into a special room. The mirror goes inside a vacuum chamber. This chamber takes out air and dust, so the space is very clean. Workers use aluminum-covered tungsten wires to put a thin metal layer on the mirror. Once the aluminum turns into vapor, the coating step takes less than a minute.

Coating telescope mirror needs a surface that is very clean and smooth. A smooth mirror helps the coating stick well. If the mirror is dirty or scratched, the coating might not work right. Problems on the surface can cause the coating to not work as well.

A clean and smooth surface helps the coating stick and spread evenly.

Dirt or bumps on the mirror can make the coating not work right.

Getting a mirror finish means carefully removing bumps and making the surface shiny and flat.

When the coating is done right, the mirror bounces back light well and lasts longer. If the coating is not done well, problems can happen.

More light gets scattered

The mirror does not reflect as much light

The shape of the light waves can get messed up, causing blurry images

The coating may not last as long and can stop working well

If the shiny coating gets worse, too much light can scatter. If the coating is not even, the mirror can make the light waves rough. Tiny holes or cracks in the coating can block light.

Coating telescope mirror is very important for making telescopes work their best. Good coating makes images better, keeps the mirror safe, and helps it last longer.

Aluminum coating is the most used for telescope mirrors. Technicians put a thin aluminum layer on the glass. This layer reflects about 90% of visible light. It helps telescopes show bright pictures. Aluminum works well with ultraviolet and infrared light too. This makes it good for many kinds of viewing. The aluminum layer is only a few hundred nanometers thick. This thin layer reflects light well and does not make the mirror heavy.

Aluminum coatings work well for both amateur and professional telescopes. They do not tarnish as quickly as silver in some places.

Silver coatings reflect more light than aluminum. Silver can reflect up to 95% of visible light. Telescopes with silver coatings can show dim objects and small details. Enhanced silver coatings are better than regular silver and aluminum coatings:

High reflectivity is over 95%, so telescopes get more light and clearer pictures.

Low light absorption means less heat, which keeps the optics working well.

These coatings last longer and resist damage from the environment.

A smooth surface scatters less light and makes images sharper.

Silver coatings do not work as well as aluminum with ultraviolet and infrared light. But their high reflectivity in visible light makes them good for research telescopes that need bright images.

Mirror coatings need protection from scratches and damage. Technicians add a protective layer over the metal. Silicon Monoxide (SiO) is often used for aluminum mirrors. This material makes the surface tough and stops oxidation. Dielectric coatings also make the mirror stronger and safer to handle.

| Material | Benefits |

|---|---|

| Silicon Monoxide (SiO) | Makes the surface tough and protects aluminum mirrors. |

| Dielectric Coatings | Makes the mirror last longer, easier to handle, and protects against oxidation without hurting performance. |

Weather can change how long mirror coatings last. Humidity and salty air can make coatings wear out faster. Using a stronger overcoat like silicon dioxide (SiO2) helps coatings last longer in tough places. Where the telescope is used affects how long the coatings stay good.

Telescope owners should think about the weather and where they store their telescope. This helps keep mirror coatings safe and working well.

Image Source: pexels

Cleaning the mirror the right way helps it work well. Experts say to use gentle cleaning so you do not scratch it. They take the mirror out of its holder before cleaning. First, they rinse the mirror with tap water. Then, they put a little dish soap on it and swirl gently. After that, they rinse with distilled or de-ionized water. Last, they blot the mirror with a clean towel or cloth. Do not touch the front of the mirror because it can hurt the coating.

Warm water mixed with mild soap like Ivory Liquid works best. Some people use 1 ounce of soap for every liter of distilled water. This can help clean better. Tests show CO2 cleaning makes the mirror reflect about 1% more light. It also makes scattering ten times better. But do not use CO2 cleaning if humidity is over 40%. It can damage the aluminum layer.

| Cleaning Method | Frequency | Effectiveness | Notes |

|---|---|---|---|

| CO2 Cleaning | Monthly | Makes reflectivity better and lowers scattering | Do not use if humidity is over 40% |

Keeping dust and moisture away from the mirror keeps images clear. Telescope owners use covers and caps to block dirt. After using the telescope, they bring it inside. They let it warm up to room temperature. This helps moisture go away. Many people put desiccant packs or silica gel in the case. This keeps humidity low.

Optical surfaces can get dirty from water vapor, dust, and gases. Dust can blow onto mirrors and stick, making a film. This film can make images worse. Moisture and dust together can hurt the coating.

Cleaning often gets rid of dust and dirt on the mirror. Experts clean off things like pollen or animal waste fast. These things can damage the surface. They watch for signs of corrosion like dull spots or tiny holes. Small problems do not always need fixing right away. The goal is to keep the mirror cleaner. Coatings do not always look perfect after the first time. Careful cleaning helps the coating last longer.

Telescope owners sometimes ask when to recoat their mirrors. There are some signs that show a mirror needs a new coating. The mirror might look dull and not shine like before. If you see lots of pinholes, the coating is wearing out. A few pinholes are normal, but too many is bad. Corrosion or cloudy spots can also show up. These make images look less sharp.

When these things happen, the mirror does not reflect light well. Astronomers see dimmer pictures and more scattered light.

Professional recoating services give good results. These companies follow strict steps to check quality. Technicians clean and check each optical part before coating. They watch the coating process very closely. Quality checks make sure every mirror is up to standard.

The process has many inspections and safe removal of old coatings. New layers are put on with care. Owners get their mirrors back after a final check.

| Service Provider | Turnaround Time |

|---|---|

| Majestic Coatings | 1 week or less |

| Precision Applied Products | Please call for current times |

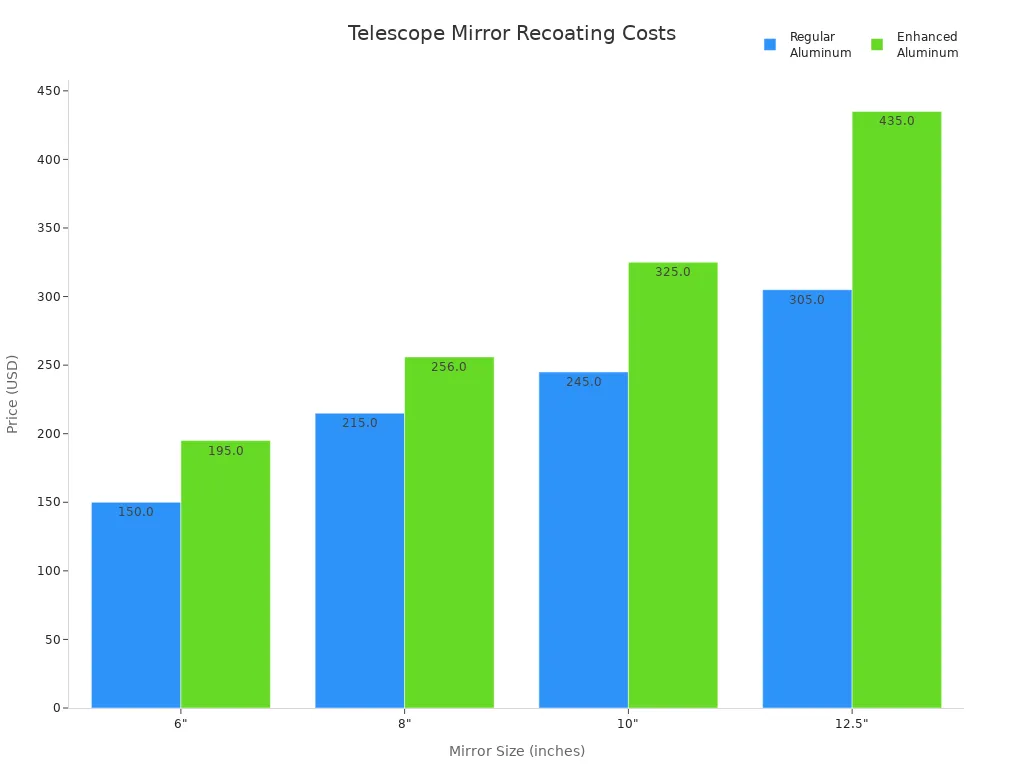

| Mirror Size | Regular Aluminum Price | Enhanced Aluminum Price |

|---|---|---|

| 6" | $150.00 | $195.00 |

| 8" | $215.00 | $256.00 |

| 10" | $245.00 | $325.00 |

| 12.5" | $305.00 | $435.00 |

Secondary mirror prices only count if sent with the main mirror.

Some people try to recoat their mirrors at home to save money. They need special tools and supplies to do this. DIY methods can work, but there are risks. Aluminum coatings can scratch and tarnish fast. Without a protective layer, mirrors need new coatings more often. Taking off old coatings can hurt the glass. If you do not handle the mirror right, it can get ruined.

Experts say mistakes can hurt how well the mirror works. Many suggest using regular aluminum coatings, not fancy ones. Careful work and handling help the new coating last longer and keep images clear.

Taking care of the mirror and coating helps telescopes show bright and clear pictures. People who own telescopes should keep these things in mind:

Use gentle cleaning so you do not scratch the coating.

Take off dust and dirt with distilled water when needed.

Do not use rough things that can hurt the surface.

Looking after the mirror often helps it last longer.

You can find more advice in telescope manuals and astronomy forums. These places have good guides for mirror care and recoating.

Experts say to clean the optical surface only when it looks dirty or the image gets worse. Cleaning too much can hurt the coating. Owners should check the optical surface every few months.

Dust, moisture, and scratches can harm the optical surface. Touching the mirror with bare hands leaves oils. These oils make the mirror reflect less light. Using rough things to clean can scratch the optical surface.

Small marks on the optical surface may not change how it works. Deep scratches or rust need help from professionals. Trying to fix it at home can make the optical surface worse. Owners should not use strong chemicals or sharp tools.

A protective layer keeps the optical surface safe from rust, scratches, and wet air. This coating helps the optical surface stay shiny and last longer. Without protection, the optical surface gets worse quickly.

Keep the telescope in a dry place with no dust. Put a cover on it to keep dirt away. Silica gel packs help stop moisture. Do not store near chemicals or in wet spots.