close

Choose Your Site

Global

Social Media

Views: 0 Author: Site Editor Publish Time: 2025-11-07 Origin: Site

Leading companies in Optical Filter CNC cutting are band-optics, Sydor Optics, Edmund Optics, Optical Filters USA, Torrent Photonics, Shanghai Optics, Pynco, IBS Coating Optics, Omega Optical, and Alluxa. Each company has its own special skills. Band-optics has over ten years of optical engineering work. They have a modern metrology lab and give custom optical help. The table below shows their main skills:

| Unique Capability | Description |

|---|---|

| Optical Engineering Experience | More than 10 years in optical engineering and making parts. They can help from first idea to big orders. |

| Metrology Laboratory | They can test optical parts very carefully. They follow ISO9001:2015 rules for good quality. |

| Custom Optical Services | They make special opto-mechanical parts. They can build samples and use new ways to make things. |

Top companies also use double-sided lapping, high-speed polishing, MRF polishing, and CNC grinding to get the best results.

Pick manufacturers with good precision and quality certificates like ISO 9001:2015. This helps you get reliable optical filters.

Learn about the types of optical filters and how they are used. This helps you choose the right product for your needs.

Write down your needs in detail before asking for quotes. This helps manufacturers give you correct prices and timelines.

Find companies that have helpful customer support and fast lead times. This keeps your projects moving forward.

Keep up with new cutting technologies. This helps you use the best ways to make optical filters.

Image Source: pexels

CNC cutting shapes optical filters very precisely. Makers use special machines to cut glass and ceramics. These machines work fast and help save materials. Endless diamond wire saws make smooth cuts and keep things even. Automatic glass cutters check force and speed to avoid errors. Ceramic cutters work with hard sheets and make filters stronger. Complex contour cutting helps each filter fit the right size. Automation makes fewer mistakes and speeds up work.

New technology has made the process better. High-speed machines finish jobs faster. Precision engineering gets accuracy within five microns. Fanuc controls help keep quality the same. Automation helps with big orders. Faster spindle speeds make cycles shorter.

| Advancement Type | Description |

|---|---|

| Industrial Optical Filter Shaping Machine | Machines that cut glass or ceramic neatly, saving time and materials. |

| Endless Diamond Wire Saw | Sharp saws that waste less material and make even cuts. |

| Automatic Glass Cutting Machines | Smart machines that check force, speed, and alignment to stop mistakes and work better. |

| Ceramic Cutting Machines | Built for tough ceramic sheets, good for hard jobs, and make filters last longer. |

| Complex Contour Cutting | Special machines that cut exact shapes and waste less by being accurate. |

| Automation Integration | Cuts down on human mistakes and makes production faster with automatic feeding and cutting. |

Optical filter CNC cutting helps many fields. Medical and biotech companies use bandpass filters to pick certain wavelengths for pictures and tests. Semiconductor makers need narrow laser line filters for exact wavelength choices. Aerospace companies want strong filters, often made with ceramic cutters, for tough places. Laser tech uses notch filters to block extra light and make systems work better.

The table below shows how each filter type is used:

| Filter Type | Application Description |

|---|---|

| Bandpass Filters | Pick certain wavelengths, important for tests and pictures. |

| Shortpass and Longpass | Let only short or long wavelengths go through. |

| Dichroic and Polychroic | Split beams, used in microscopes to send light different ways. |

| Notch Filters | Block certain light, needed for jobs that let some light pass but stop others. |

| Multiband Filters | Help find many signals at once, good for multi-fluorophore uses. |

| Narrow Laser Line Filters | Pick exact laser lines, needed for very careful work. |

Optical filter CNC cutting makes sure every filter is made right. Many industries count on this process for good results and strong performance.

Image Source: pexels

Manufacturers need to be very exact when making optical filters. They use advanced CNC machines for tight measurements. The main materials are optical glass, crystalline materials, plastics, and metals. Each material works in its own way. Optical glass, like BK7 and fused silica, lets light pass well and stands up to tough places. Crystalline materials, such as sapphire and calcium fluoride, can handle very hot or cold temperatures. Plastics, like acrylic and polycarbonate, are light but not as clear. Metals, including aluminum and gold, are used for mirrors.

Optical glass: BK7, fused silica

Crystalline materials: sapphire, calcium fluoride

Plastics: acrylic, polycarbonate

Metals: aluminum, gold

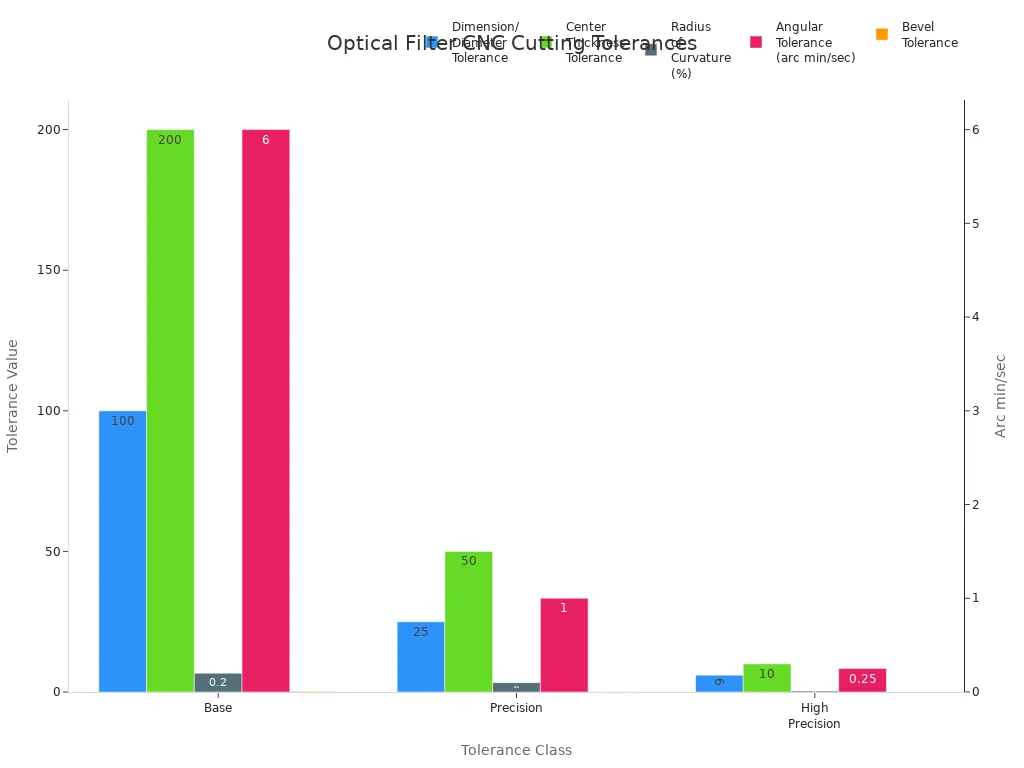

Manufacturers must follow strict tolerance rules. The table below shows the usual tolerances for optical filter CNC cutting.

| Tolerance Class | Dimension/Diameter Tolerance | Center Thickness Tolerance | Radius of Curvature | Angular Tolerance | Bevel Tolerance |

|---|---|---|---|---|---|

| Base | 100 μm | 200 μm | 0.2% | 6 arc min | 0.2 mm |

| Precision | 25 μm | 50 μm | 0.1% | 1 arc min | 0.1 mm |

| High Precision | 6 μm | 10 μm | 0.01% | 15 arc sec | 0.02 mm |

Quality is important for every optical filter maker. ISO9001:2015 certification means a company follows strict rules for quality. This shows the manufacturer can make products that meet customer needs and follow laws. The table below explains this certification.

| Certification | Description |

|---|---|

| ISO9001:2015 | Shows strong quality control and cares about customer happiness. Makes sure products meet what is expected. |

Customers want their orders fast and need good help. Most manufacturers ship custom orders in about three weeks. Big orders or hard parts may take longer. The table below shows normal lead times.

| Lead Time | Description |

|---|---|

| 3 weeks | Most orders ship in three weeks. Special jobs may take more time. |

Top manufacturers also give great customer support. They answer questions, fix problems, and share helpful guides. The table below lists common support services.

| Service Type | Description |

|---|---|

| Customer Support | Helps with questions and orders. |

| Technical Support | Fixes problems and gives advice. |

| Resources & Downloads | Shares guides and useful documents. |

| Global Feedbacks | Gets feedback from customers everywhere. |

Tip: Picking a manufacturer with good support and quick shipping helps projects finish on time and reach quality goals.

Band-optics is a top company in Optical Filter CNC cutting. The company started in 2008. It now helps customers all over the world. Band-optics uses new technology and strong quality checks. This helps them make optical parts you can trust. Their team knows a lot about making things with high accuracy. They also create custom solutions for special needs.

The table below shows what band-optics does best:

| Core Features | Description |

|---|---|

| Precision Engineering | Made with great care to meet tough rules and customer needs. |

| Diverse Product Range | Sells many optical parts like lenses, prisms, filters, domes, and windows. |

| Customization Expertise | Makes special designs and coatings for different jobs. |

| Quality Assurance | Checks every part to make sure it works well and lasts. |

Band-optics makes many kinds of filters for different jobs. Their products include:

Eccentric spectroscopic filters

Depolarizing filters

Fluorescent filters

Long-pass filters

Short-pass filters

Face recognition filters

Enzyme label filters

Astronomical observation filters

UV filters

Color sorting filters

Band-optics has ISO 9001:2015 certification. This means they care about quality and helping customers. The company gives good optical parts for medical, laser, and aerospace work. Their careful work and custom help let customers reach their goals.

Note: Band-optics uses careful engineering, many products, and strong quality checks to help with tough jobs.

Other companies are also leaders in Optical Filter CNC cutting. Each one has its own strong points and products.

The table below shows some big companies and what they do best:

| Company | Strengths | Product Ranges |

|---|---|---|

| Shanghai Optics | Makes strong filters that last long and let lots of light through | Sells dichroic filters, colored glass filters, shortpass, longpass, and bandpass filters |

| Alluxa | Makes custom filters and coatings with high accuracy | Sells ULTRA Series filters like bandpass, notch, dichroic filters, and dielectric mirrors |

Other important companies are Sydor Optics, Edmund Optics, Optical Filters USA, Torrent Photonics, Pynco, IBS Coating Optics, and Omega Optical. These companies make many optical parts for science, industry, and technology. They focus on making things exact, strong, and custom for each job.

Tip: When picking a company, look at their experience, what they sell, and their quality awards. Good companies help your project work well and last a long time.

Optical filter CNC cutting companies have different skills and services. The table below shows how band-optics and other top companies compare. It looks at things like precision, custom solutions, industries, certifications, delivery time, and customer help.

| Criteria | band-optics | Shanghai Optics | Alluxa | Edmund Optics |

|---|---|---|---|---|

| Precision Workmanship | Ultra-tight tolerances, ISO 9001:2015 | High precision, ISO certified | Advanced thin-film precision | Reliable tolerances, ISO certified |

| Complexity Solutions | Custom shapes, CNC, MRF, rapid prototyping | Custom shapes, CNC | Complex filter designs | Standard and custom solutions |

| Industry Diversity | Medical, laser, semiconductor, aerospace | Scientific, industrial, medical | Research, industrial, medical | Education, research, industrial |

| Certifications | ISO 9001:2015 | ISO 9001:2015 | ISO 9001:2015 | ISO 9001:2015 |

| Lead Time | 3 weeks typical, flexible for custom orders | 3-4 weeks | 2-3 weeks | 2-4 weeks |

| Customer Support | Technical help, fast response, global service | Technical support, guides | Dedicated support, resources | Online help, technical support |

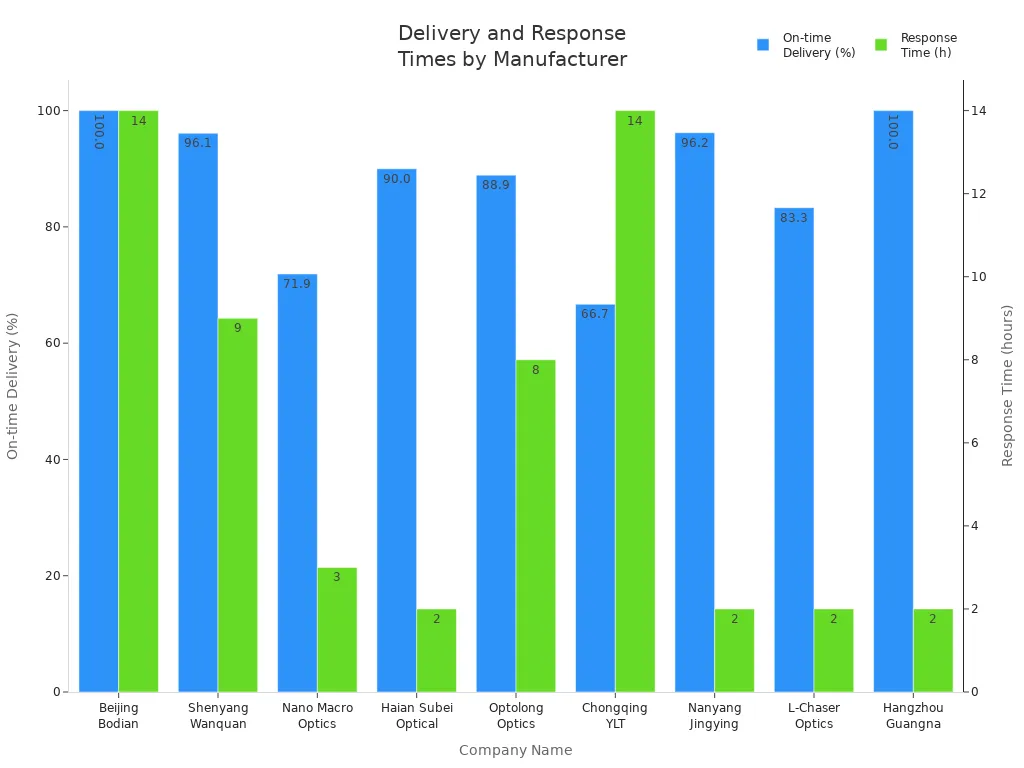

Some companies are better at shipping on time and answering fast. The chart below shows how well top companies do these things.

Band-optics is known for very careful work. They use special CNC machines and labs to get tight tolerances. Band-optics can make custom shapes for hard jobs. They work with many materials like optical glass, fused silica, sapphire, and metals.

Shanghai Optics and Alluxa also do high precision and custom filters. Edmund Optics is good for steady tolerances and helps schools and research. All these companies have ISO 9001:2015, which means they care about quality.

Delivery times are not the same for every company. Band-optics usually ships in three weeks and can change for special jobs. Alluxa often ships in two to three weeks. Customer help is different too. Band-optics gives fast answers and technical help everywhere. Other companies give guides, online help, or special support teams.

Tip: Pick a manufacturer with good precision, material choices, certifications, quick shipping, and strong customer help. These things help your project go well.

Customers should get all details ready before asking for a quote. This helps the company know what you need and give the right price. Here is what you should collect:

Company or organization name

First and last name of the contact person

Address

Phone number

Email address

Website

Application details for the optical filter

Substrate material (such as glass, sapphire, or metal)

Size of the filter

Quantity needed

Coating type and surface to be applied

Additional services (for example, busbar, laser etching, masking, serialization)

Quality control or MIL-Spec requirements

Estimated completion date

Drawing or design file (accepted formats include jpg, gif, png, pdf, doc, docx; maximum file size is 10 MB)

Giving clear and full information helps the manufacturer reply fast and correctly. This also lowers the chance of mistakes when making your order.

Tip: If you add a drawing or design file, it helps the company know exactly what you want.

Talking well helps customers and manufacturers work together better. Customers should use easy words and not use hard technical terms. They should ask simple questions about delivery time, price, and materials. If you have special needs, say them early.

Here is a table with good ways to talk:

| Practice | Benefit |

|---|---|

| Clear descriptions | Reduces confusion |

| Early mention of needs | Speeds up the process |

| Quick responses | Keeps the project moving |

| Sharing contact details | Ensures fast follow-up |

Manufacturers like band-optics like clear and quick talking. They answer questions and help customers at every step. Customers who reply fast help the project finish on time.

Note: Good talking helps build trust and gives better results for everyone.

Manufacturers have many problems when cutting optical filters. Machines need clean air to work well. Dust, oil, and water can cause trouble if not removed. The laser’s path must stay safe for good results. Sometimes materials act in ways you do not expect. Optics can wear out and stop working well. Gases used in cutting can change or get dirty. Motion systems have limits that affect how exact the cuts are. Safety rules and laws make the job harder. High costs and needing skilled workers make things tough. Checking quality needs careful work and money.

Machines need clean air to keep dust, oil, and water out.

Keeping the laser’s path safe helps it work well.

Materials can act in strange ways when cut.

Optics can wear out and not work as well.

Gases can change or get dirty during cutting.

Motion systems can only do so much.

Safety and environment rules make things harder.

High costs and needing good workers make it tough.

Checking quality needs careful work and money.

Fixing machines often stops surprise problems.

Cleaning gas lines and tanks keeps things clean.

Buying good gas from trusted sellers helps avoid trouble.

Tip: Fixing machines often and planning well helps stop many problems.

Top manufacturers use smart ways to fix these problems. They buy fast machines that finish jobs quickly and keep quality high. Diamond wire cutting makes strong edges and stops chips, so filters last longer. Careful cutting saves glass, quartz, or sapphire. Computer software helps shape parts and stops mistakes. Low vibration systems keep glass from cracking or getting rough edges. These new ways help companies make good products and save money.

| Feature/Benefit | Description |

|---|---|

| High-Speed Operation | Fast machines finish big orders quickly and keep quality high. |

| Enhanced Durability | Diamond wire cutting makes strong edges and stops chips, so filters last longer. |

| Waste Reduction | Careful cutting uses more material and saves money. |

| Long-Term Cost Savings | Good machines make high-quality filters with less waste, saving money over time. |

| Improved Performance | Well-shaped filters work better in many jobs. |

| Advanced Cutting Techniques | Diamond wire cutting gives smooth, strong results. |

| Computer-Controlled Shaping | Software helps shape parts, stops mistakes, and keeps things the same. |

| Low Vibration Performance | Special systems lower vibration and stop cracks or rough edges in glass. |

Note: Companies that use these smart ways can meet tough quality rules and give strong, good optical filters to many industries.

Picking the best optical filter CNC cutting manufacturer is important for your project. Top companies give accurate work, good quality, and helpful support. Band-optics is special because it uses new technology and has ISO certification. Customers should look at what products each company sells, how fast they deliver, and what help they offer.

Look at what each manufacturer does well.

Make sure they have the right certifications and lots of experience.

Ask for simple price quotes and some samples.

Tip: Band-optics gives trusted help for medical, laser, semiconductor, and aerospace projects.

Manufacturers use optical glass, fused silica, sapphire, silicon, metals, and plastics. Each material works best for certain jobs. Band-optics uses many materials to help customers.

ISO 9001:2015 means the company checks quality very carefully. Customers get products that follow strict rules. Band-optics uses these rules for every order.

Most companies send custom filters in about three weeks. Big orders or special designs can take more time. Customers should ask how long delivery will take.

Many companies give samples for testing. Customers can ask for samples to check quality and fit. Band-optics lets customers try samples before buying a lot.