close

Choose Your Site

Global

Social Media

Views: 0 Author: Site Editor Publish Time: 2025-10-24 Origin: Site

A custom optical prism is a special glass or crystal. It changes how light moves. Standard prisms are not made for special jobs. Engineers make these prisms for certain tasks in devices. Each prism design fits what different industries need. For example, laser systems need prisms to be very exact. Ophthalmic devices use them in lenses and tools. The table below shows where these prisms are important:

| Industry | Applications |

|---|---|

| Laser Systems | Custom optical prisms for precision and efficiency |

| Ophthalmic Devices | Used in corrective lenses and diagnostic tools |

| Aerospace Instrumentation | Essential for navigation and imaging systems |

| Smart Optical Solutions | Emerging technologies utilizing adaptive optics |

Custom optical prisms are made to change how light moves. They are built for special jobs in many industries. These prisms can bend, split, or reflect light. This makes them important in lasers, telescopes, and medical tools. Picking the right material and design is very important. It changes how well the prism works for its job. Custom prisms help devices show clearer and more correct images. This gives better results in science, medicine, and technology. Engineers talk with customers to make prisms for their needs. This helps each device work its best.

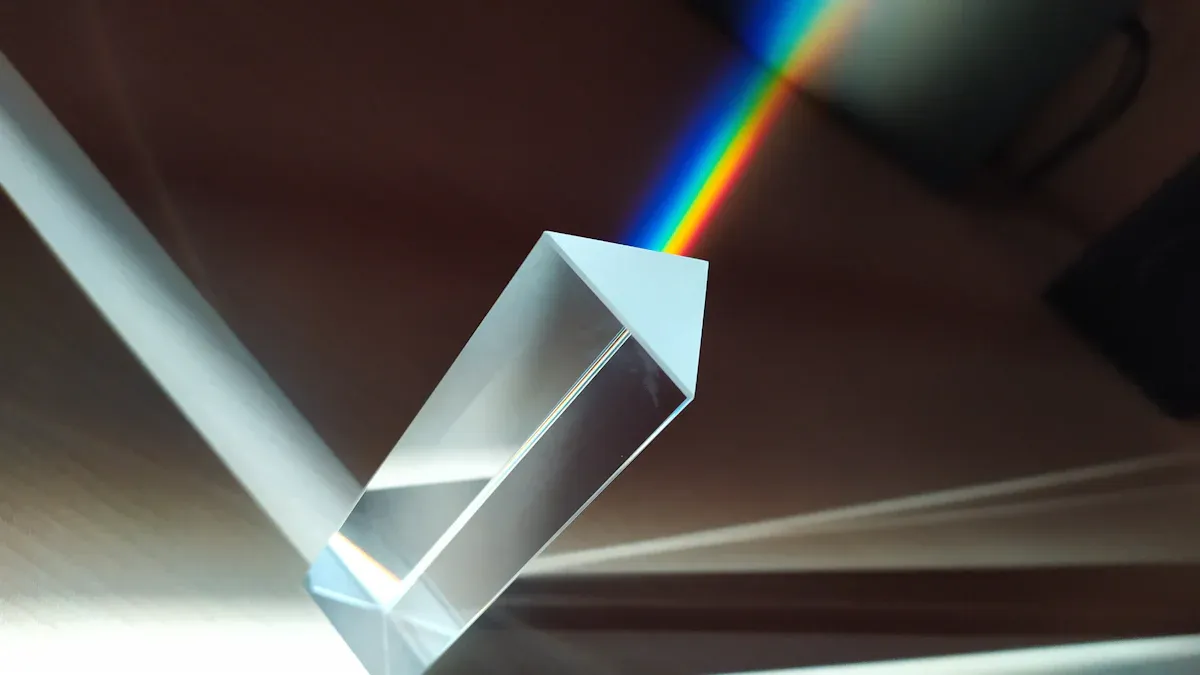

Image Source: pexels

A custom optical prism is clear and made from glass or crystal. It has flat sides that meet at different angles. These sides do not run side by side. The main job is to change how light moves inside it. It can bend, split, or turn light beams. Engineers make these prisms for special uses in science, medicine, and technology.

The table below explains what optical prisms are and what they do:

| Definition | Function |

|---|---|

| Optical prisms are clear parts with many flat sides that meet but are not side by side. | They change light by bending, moving, or turning light beams or pictures using certain angles. |

Custom optical prisms use a few ways to change light:

Light Refraction: The prism bends light as it goes through, making it go a new way.

Dispersion of Light: The prism splits light into many colors, like a rainbow.

Total Internal Reflection (TIR): The prism bounces light inside itself and sends it out at a new angle without losing brightness.

These things help guide light in tools like telescopes, microscopes, and periscopes. Scientists also use them to look at light closely.

Standard prisms have set shapes and sizes. They are good for simple jobs, but sometimes more is needed. A custom optical prism can have special shapes, sizes, and angles. This helps it fit just right in a device or system. Custom prisms can fix problems that standard ones cannot.

Custom optical prisms are made for special needs. Engineers talk to customers to find out what they want. They look at the shape, size, and how the prism should work with light. This helps make prisms that help laser systems work better or make camera images clearer.

Flatter surfaces and exact angles, which help split laser beams or study light.

Better results in medical pictures and science studies.

New designs that help technology get better.

For example, some companies made custom prisms for laser surgery. These prisms help doctors aim laser beams better, making treatments safer and more exact. In space work, custom prisms have made pictures from space clearer.

Note: Custom optical prisms let engineers make systems that work better and do more than regular prisms can.

Custom prisms change the path of light by using the physical properties of glass or crystal. When light enters a prism, it slows down or speeds up, depending on the material. This change in speed causes the light to bend. The amount of bending depends on the angle of the prism and the type of material used.

Light bends because each color travels at a different speed inside the prism. This happens due to the refractive index, which is different for each color.

When light hits the surface at a steep angle, it can bounce back inside the prism. This is called total internal reflection. It helps direct light without losing brightness.

The angle at which light enters and leaves the prism affects how much the light bends. The shape and size of the prism also play a role.

Note: The bending and reflection of light in custom prisms follow rules like Snell’s law. This law explains how light changes direction when moving between air and glass.

Custom prisms do more than just bend light. They can also rotate images and split light into its colors. These features help in many optical systems.

| Functionality | Description |

|---|---|

| Beam Deviation | Custom prisms control the angle of light, which is important for rotating images. |

| Image Orientation | They can keep an image upright or flip it, depending on the design. |

| Spectral Dispersion | Prisms split white light into different colors, making it easier to study each part. |

When white light passes through a prism, each color bends at a different angle. This process, called dispersion, creates a rainbow effect. Scientists use this to study the makeup of light. In cameras and telescopes, prisms can rotate or flip images so they appear correctly to the viewer. Custom prisms allow engineers to design systems that need special image orientation or color separation.

Right-angle prisms look like triangles with two 45° angles and one 90° angle. They can change the direction of light very accurately. These prisms do not make much distortion. Many companies use them because they control light so well. The table below shows what they do and where they are used:

| Characteristic/Application | Description |

|---|---|

| Precision Optical Systems | They move light with very small errors and let almost all light pass through. |

| Industrial Measurement & Alignment | They help machines and lasers line up things very carefully. |

| Scientific Instruments | They are used in science tools for studying space and tiny particles. |

| Defense & Aerospace | They are strong and work in hard places, like in planes or for the military. |

Dove prisms flip images by bouncing light inside them. When light goes in, it hits the bottom and comes out the other side, turning the image upside down. If you turn the prism, the image turns twice as much. These prisms are used in space studies, special measuring tools, and to spin images in some machines.

| Functionality | Description |

|---|---|

| Image Inversion | They turn images upside down by bouncing light inside. |

| Image Rotation | They spin images at double the angle you turn the prism. |

| Applications | They are used in space science, measuring tools, and machines that spin images. |

Penta prisms turn light by 90 degrees but keep the image straight up. This is important when things need to be lined up just right. They still work well even if they move a little, so many tools use them.

Wedge prisms have slanted sides that push light a little bit. They help with laser pictures, moving beams, and seeing different colors. Many machines use them to see better or measure how far things are. Telescopes use them to change where light goes.

| Application | Description |

|---|---|

| Laser Imaging | They help make clear laser pictures. |

| Beam Steering | They move laser beams in different directions. |

| Multi-Spectral Imaging | They help see many colors at once. |

| Machine Vision | They make machines see better. |

| Range Finding | They help measure how far away things are. |

| Telescopes | They change the path of light in telescopes. |

You can use wedge prisms alone or together.

Turning two wedges together lets you change where the beam goes.

They help shape beams and change how colors spread out.

Some tools need special prism shapes. These include glued prisms, rods that mix light, rhomboid prisms, and prisms with nine sides. These special prisms can split or join many beams, move beams very exactly, or separate colors in tricky ways.

Some prisms can split or join many light paths at once.

Special angles help move beams exactly where needed.

Some prisms can filter or spread out colors in special ways.

Rhomboid prisms move light to the side but do not change its direction. This helps in binoculars and microscopes.

Picking the right prism is important for how well a system works. For example, custom prisms with flat sides and exact angles can help lasers scan or take pictures better. Some systems use liquid prisms that can change without moving parts, making them easier and faster to use.

Image Source: pexels

Custom optical prisms are very important in science tools. Scientists use these prisms to move, bend, or split light in exact ways. Many tools need these prisms to work well.

Laser technology: Prisms help lasers work better and more exactly. This matters for research and for sending messages.

Telescopes: Prisms fix light problems and make pictures clearer. Astronomers use them to see stars and planets better.

Virtual reality: Prisms send light to make cool, real-looking scenes. This helps with games and training.

Custom prisms help each tool do its job best. Engineers can make each prism fit the tool’s needs. This gives sharper pictures, better checks, and more trust in results.

Doctors and scientists use custom optical prisms for better pictures and tests. These prisms help medical tools show clearer and more detailed images. The table below shows how they help medical technology:

| Benefit/Role | Description |

|---|---|

| Enhanced Image Clarity | Prisms give clearer and more correct pictures for tests. |

| Improved Diagnostic Accuracy | They help find problems like brain injuries and seizures. |

| Detailed Imaging | Prisms show more details, helping doctors plan treatments. |

| Image Combination | They can mix different pictures for a full view. |

| Advanced Imaging Systems | Special shapes make pictures sharper, showing tiny blood vessels and tissues. |

| Endoscopic Use | Prisms in endoscopes let doctors see around corners and in hard places. |

| Microprisms | These small prisms guide light, making pictures clearer in tight spots. |

Custom prism designs help doctors see more and find problems faster. They also let doctors mix pictures from different scans for a full look at a patient’s health. This means better care and more success in treatments.

Imaging and sensing systems use custom optical prisms to control light and make pictures better. These systems are in cameras, projectors, and sensors in factories. Custom prisms help focus light, change the view, and make images sharper. Prism stacks can be checked using special light tests, which help with projectors and measuring movement.

Some main benefits are:

Sharper focus and clearer pictures in cameras and projectors.

Better accuracy in sensors that check distance or movement.

Good performance even when things change.

Custom prisms let engineers match the prism to what each tool needs. This makes devices work better and last longer.

Custom optical prisms are needed in defense and industry. In defense, these prisms help targeting pods find and follow things. Special coatings let some light through, so people can see in fog or dark. High-energy lasers use custom prisms to stop light from spreading out, which keeps them from getting too hot or breaking. Ring laser gyroscopes in planes and military cars use prisms with smooth sides and shiny surfaces for good navigation.

In industry, custom prisms help machines see and check products. They guide lasers for cutting, measuring, and checking things. These prisms must be strong because they work in hard places.

The table below shows the main benefits in all areas:

| Benefit | Description |

|---|---|

| Precision | Custom optical prisms make pictures better by fixing focus, view, and quality. |

| Durability | Made to work in tough places, so they last a long time. |

| High Performance | Smart designs help optical systems work well, balancing picture quality and how easy they are to make. |

Custom optical prism solutions help each tool do its best work. They make things more accurate, reliable, and high-performing in every area.

Manufacturers use many materials to make custom prisms. Each material has special features for certain jobs. The table below lists some common materials:

| Material Type | Optical Properties |

|---|---|

| Glass | Clarity, thermal stability, low dispersion rates |

| Borosilicate Glass | Resistance to temperature changes |

| Fused Silica | Exceptional optical purity and stability |

| Sapphire | Hardness, scratch resistance |

| Infrared | Infrared transmission capabilities |

| PMMA | Lightweight, easily molded |

| Polycarbonate | Versatile, economical |

Choosing the right material depends on the prism’s design and use. Glass or fused silica is good for exact work. PMMA is better for light and simple uses.

Coatings and finishes help prisms work better and last longer. Different coatings do different things:

Optical coatings help more light pass through and cut down on glare. This makes images clearer.

Low-reflective coatings are best for medical tools and fancy cameras. They give sharp pictures with less shine.

Diamond-like carbon films let more light through and soak up less. These films help infrared prisms last longer and work better.

Some materials, like Infrared, are extra hard and cut down on glare. This makes them good for camera lenses and glasses.

Tip: The right coating can really help a prism work better and last longer.

Making custom prisms takes careful steps to get good results. The table below shows some common ways to make them:

| Manufacturing Technique | Impact on Precision | Impact on Cost |

|---|---|---|

| CNC grinding | High precision, complex shapes | Higher initial cost, good for large runs |

| Polishing | Better surface quality | Adds time and cost |

| Coating | Improves optical performance | Cost varies by material and complexity |

| Additive manufacturing | Good for prototypes | Higher cost for small batches |

Manufacturers must keep surfaces smooth and shapes just right. Using machines helps stop mistakes and keeps quality high.

Ordering custom prisms has a few steps:

Decide what you need, like size and how well it should work.

Send your request to the company with all the details.

Look at the price and how long it will take.

Say yes to the order if you agree with everything.

Customers should agree on all the details, like size, coatings, and material. This makes sure the prism works for what you need.

Custom optical prisms are very important in today’s cameras and sensors. They help make pictures clearer and more steady. They also help tools measure things more exactly. These prisms are used in many places, like in hospitals and on drones. Picking the right kind of prism and material makes devices work better. Experts at companies like VY Optics and Precision Optical help people choose and make these prisms. If you want to learn more, you can look at examples and other resources.

| Future Trend | Industry Impact |

|---|---|

| Compact designs | Lighter devices in electronics |

| Advanced coatings | Better performance in harsh settings |

| Quantum technologies | New uses in science and computing |

Tip: Talk to optical engineers to get the best custom prism for your needs.

A custom prism has a special shape, size, or coating. Engineers design it for a specific job. Standard prisms have set shapes. Custom prisms fit unique needs in science, medicine, or industry.

Engineers look at what the prism must do. They check if it needs to handle heat, light, or chemicals. They pick glass, crystal, or plastic based on these needs.

Yes. Custom prisms can make images clearer and sharper. They help focus light better and reduce errors in cameras, microscopes, and other devices.

People use custom prisms in lasers, cameras, telescopes, medical tools, and machines that measure things. These prisms help guide light and improve how devices work.

The time depends on the design and material. Simple prisms may take a few days. Complex shapes or special coatings may take weeks. Engineers give a time estimate before starting.