close

Choose Your Site

Global

Social Media

Views: 0 Author: Site Editor Publish Time: 2025-10-24 Origin: Site

Custom optical prisms are very important in modern optical systems. These prisms help engineers control light very well. They let people get the right performance for each job. In advanced imaging, they help make pictures clearer and details sharper. Many experts use them to lower signal loss. They also help make devices smaller and better. Areas like biomedical imaging and communication technologies need custom optical prisms. They help give correct results and make systems work better.

Custom optical prisms help control light very well. This makes them important for imaging and laser systems. These prisms make images better by blocking unwanted light. They also fix optical errors, so pictures look clearer. Custom prisms help stop signal loss in optical systems. This keeps data strong and clear when it moves. They let devices be smaller and lighter but still work well. Custom optical prisms are very important in biomedical imaging and communication technologies. They help make things more accurate and efficient.

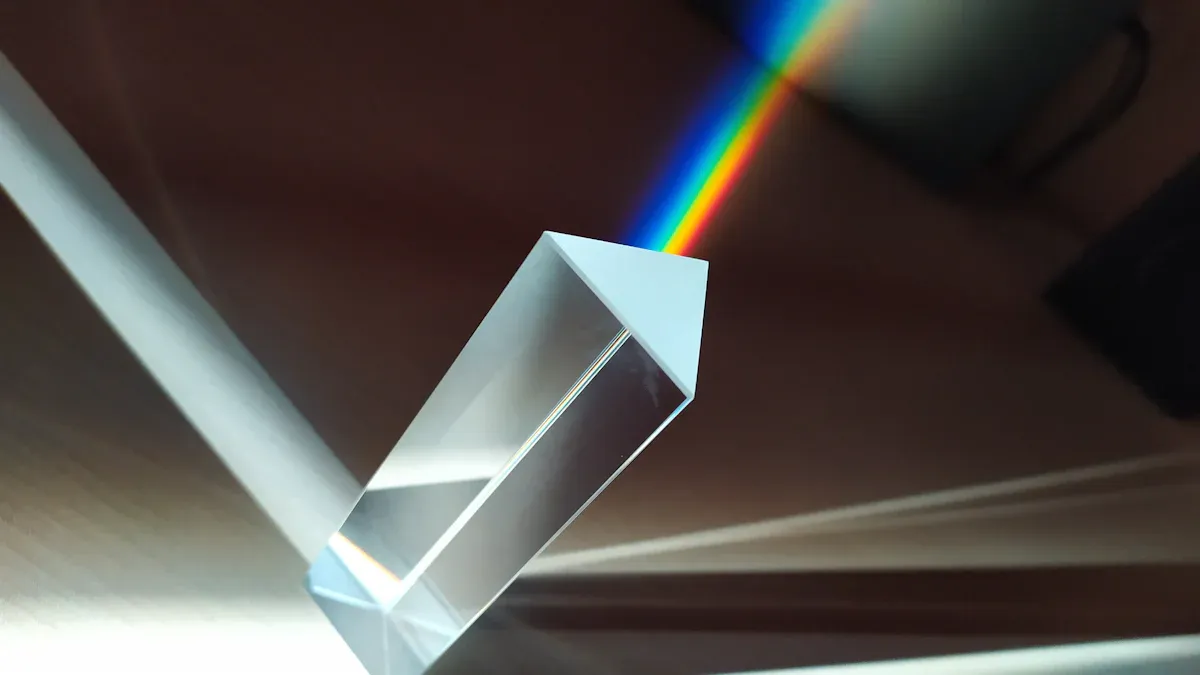

Image Source: pexels

Custom optical prisms let engineers control light very carefully. These prisms can bend, move, or turn light at exact angles. For example, they can point a beam, split it, or join it with another beam. This careful control is needed for many uses, like imaging and laser systems.

Custom Dual Amici Prisms and Dual Wedge prisms help researchers make sharp and detailed images. They also let scientists aim light exactly where it is needed in special microscopes.

Custom optical prisms can be made with very small errors, as little as 0.012mm, and angle errors less than one second of arc. These small errors mean the prisms guide light almost perfectly. The way they are made, like cutting, grinding, and polishing, makes sure each prism fits the design.

| Specification | Value |

|---|---|

| Mechanical Tolerances | Within 0.012mm |

| Angle Tolerances | Below one second of arc |

| Surface Forms | Below lambda/20 |

Custom optical prisms, especially micro prisms, are made to work with certain wavelengths. This makes them work better than regular optical parts. They also help make devices smaller and lighter, which is important for new optical systems.

Custom optical prisms help make images look better. They reduce unwanted light and focus light more exactly. In digital and smartphone cameras, micro prisms fix optical mistakes and make pictures clearer. Medical tools and laser systems use these prisms to help focus and show more detail.

Micro prisms fix optical mistakes in cameras.

They help focus in small optical devices.

Special micro-fabrication makes each prism fit its job.

Custom optical prisms help make sure every detail in an image is sharp and clear. This is important in things like biomedical imaging, where clear pictures help doctors make good choices.

Aberrations are mistakes that can blur or mess up images. Custom optical prisms fix these mistakes by guiding light carefully. They can bend or move light to fix these problems. This is very important for imaging and science tools.

Custom prisms can bend light at angles like 90° or 180°.

They can move light or even change the direction of an image.

These prisms can also flip or turn images if needed.

By fixing aberrations, custom optical prisms lower signal loss and help make small, good optical designs. They make sure all the optical parts work well together, so imaging systems work better.

Custom optical prisms help lower signal loss in many optical systems. Engineers use these prisms to guide light very accurately. This careful control keeps the light strong as it moves. In fiber optics, custom prisms direct light so data moves fast and clear. This is important for fast internet and phone networks.

Glass prisms with smooth surfaces give the best results.

Prisms with rough surfaces scatter light and hurt the signal.

Custom prisms help improve things like spatial resolution and MTF.

They also help reduce distortion and keep signals clear.

Custom optical prisms can reach high transmission efficiency like commercial gratings. They keep this efficiency over many wavelengths. When engineers add more elements to a prism, linearity improves by about 215% from one to four elements. Adding a fifth element gives a smaller boost of about 15%. These improvements show how custom prisms help keep signal loss low and make systems work better.

Custom prisms in advanced laser systems help control the laser beam. This leads to better results in surgeries and keeps patients safer.

Custom optical prisms also help make systems smaller and lighter. In medical devices, engineers use right-angle prisms made from special materials to bend light. This design lets them use total internal reflection without extra coatings. The device becomes smaller and costs less to make. By adding plano-convex aspheric lenses, they can make the system even shorter and lighter.

Micro prisms are very small and fit into tiny devices. They range from 0.1 to 5mm in size. These prisms direct light exactly where it needs to go. They do not make the device bulky. This makes them great for compact optical systems in medicine and science.

Custom prisms increase image resolution and clarity in aerospace imaging.

They help collect accurate data for space missions.

Small prisms allow for new designs that were not possible before.

Custom optical prisms let engineers build powerful systems that are small and easy to use. This helps bring new technology to many areas, from healthcare to space exploration.

Image Source: pexels

Biomedical imaging uses custom optical prisms in many ways. These prisms help guide light inside medical devices. They make images look better and show more details. Doctors use these prisms to see inside the body. This helps them find health problems early. Clear pictures from custom prisms help doctors make good choices. Biomedical engineers design prisms for special jobs, like endoscopes and confocal microscopes. These tools need sharp images and careful light control. Prisms are also used in laser systems for better focus and less signal loss. More hospitals and labs want advanced imaging for research and patient care.

Custom optical prisms help medical devices show tiny details. This lets doctors make better choices and helps patients.

Communication technologies need custom optical prisms for fast data. These prisms reflect and guide light in fiber optic cables. They help keep the signal strong and clear. Engineers use prisms in laser systems to send signals far. Corner Cube Prisms send light back to where it came from. This makes signals work better. Lidar uses prisms to measure distances with lasers. These jobs need strong signals and high accuracy. Custom prisms also help connect light in wireless systems. This keeps the signal good and makes data faster. As technology grows, more custom prisms are needed for new uses.

Custom optical prisms help fiber optic networks send data.

They keep wireless signals strong and clear.

Lidar and laser systems use prisms to measure things exactly.

Scientific instruments use custom optical prisms for many jobs. Researchers need prisms for careful measurements and experiments. Laser interferometers use prisms to split and fold light beams. Medical microscopes use prisms to save space and work better. Defense and aerospace tools use prisms to turn and scan images. Factories use prisms in lasers to shape and combine beams. Scientists use prisms for high-precision work in research and communication. These jobs need prisms to split beams and make light paths longer. Scientists pick custom prisms for accurate results and trust their measurements.

| Field | Application Description |

|---|---|

| Precision Measurement | Main parts for folding, splitting, and spreading beams in laser interferometers. |

| Medical & Bio-imaging | Small optical solutions for endoscopes and confocal microscopes. |

| Defense & Aerospace | Steady image turning and scanning in sights, periscopes, and seekers. |

| Industrial Laser Processing | Trusted prisms for combining and shaping beams in laser machines. |

| Communications & Research | High-precision optical work in quantum communication and cold atom experiments. |

Custom optical prisms help new technology grow. Engineers use these prisms to make new devices. Some of these devices were not possible before. They are used in many areas like telecommunications, medical devices, and defense. The table below shows how custom prisms help these fields:

| Application | Description |

|---|---|

| Telecommunications | Optical prisms are vital for signal processing and transmission. |

| Medical Devices | Enhance imaging clarity in diagnostic tools. |

| Defence | Improve targeting and surveillance systems. |

Custom prisms help make better optical designs. They lower distortion and help light move through better. This is important for film and photography. Factories use machines to make more prisms quickly. The quality stays high. High-index glasses make optical parts stronger and last longer. Custom manufacturing lets companies meet special needs. Research groups and companies work together to make new optical parts.

Some big new ideas include:

Special solutions for research that make things more accurate.

Wavefront guided technology that helps fix vision problems.

Using artificial intelligence to design better lenses.

Modern technology like LiDAR and augmented reality need these prisms. They help make images sharp and clear. Biomedical imaging uses them for clear pictures in OCT and endoscopy. These advances help doctors and scientists do their work better.

Custom optical prisms help companies and researchers keep up with new needs. They make optical communication work better. Now, scientists and doctors can get high-quality images. Careful checks during manufacturing make sure each prism is good.

Reflective prisms are used in both commercial and military imaging.

Special coatings turn prisms into beam splitters for more uses.

Prisms help make optical systems smaller and lighter.

Industry rules help guide how these prisms are used. Important certifications are ISO 9001 for quality and RoHS and REACH for materials. Suppliers use labs and tools to check every part. Companies want suppliers with strong quality systems and good reviews.

More people need these prisms because many industries are growing. LiDAR and AR technology are used more now. Custom optical prisms help modern technology stay ahead by meeting these needs.

Custom optical prisms make modern systems work better and last longer. They help bring new ideas to imaging, medical tools, and communication. These prisms have special shapes and materials for each job. Many industries use them for strong performance and clear results.

Custom optics make imaging and measurement more reliable and efficient.

They let engineers create special designs for medical and consumer devices.

Dove prisms help turn images and line things up in optical systems.

| Key Findings | Relevance to Custom Optical Solutions |

|---|---|

| Polarization management is very important for showing tissue details. | Custom optical designs make imaging systems stronger in tough places. |

| PS-OCT uses birefringent properties to look at the brain. | Custom optical designs are needed to map brain structures correctly. |

Engineers should pick custom solutions for their hardest optical problems.

A custom prism has its own shape or size. It can also use special materials. Engineers design it for one job only. This helps the prism fit just right. It works better than regular parts.

Engineers use custom prisms for special problems. These prisms control light more carefully. They help make devices smaller. They also make images look clearer.

Yes, custom prisms work with many kinds of light. They can handle ultraviolet and infrared light. Engineers pick the right materials and coatings. This matches the light each system needs.

Custom prisms move and focus light in medical tools. They help doctors see very small details. This helps doctors find problems early. It also helps them treat patients better.