close

Choose Your Site

Global

Social Media

Views: 0 Author: Site Editor Publish Time: 2025-10-24 Origin: Site

The material you pick is very important when making custom optical prisms. New studies say glass is very clear, strong, and not too expensive. Glass does not get damaged easily and works well with special coatings. Engineers also use fused silica, sapphire, acrylic, germanium, silicon, and ZnSe for different light types and jobs. Picking the best optical prism depends on how it works and what you need it for.

Every material has its own good points for optical prism design, helping people get exact results in many fields.

Picking the best material for optical prisms is very important. It helps get clear and correct results in many uses.

BK7 glass is a common pick because it is clear and not expensive. It also works well with coatings. This makes it good for many optical jobs.

Fused silica works well in places with high heat. It lets more than 90% of light pass through. This makes it great for lasers and space studies.

Sapphire is very hard and does not scratch easily. It is best for tough jobs where things need to last a long time.

Knowing about optical properties, strength, and price helps engineers choose the right material for their needs.

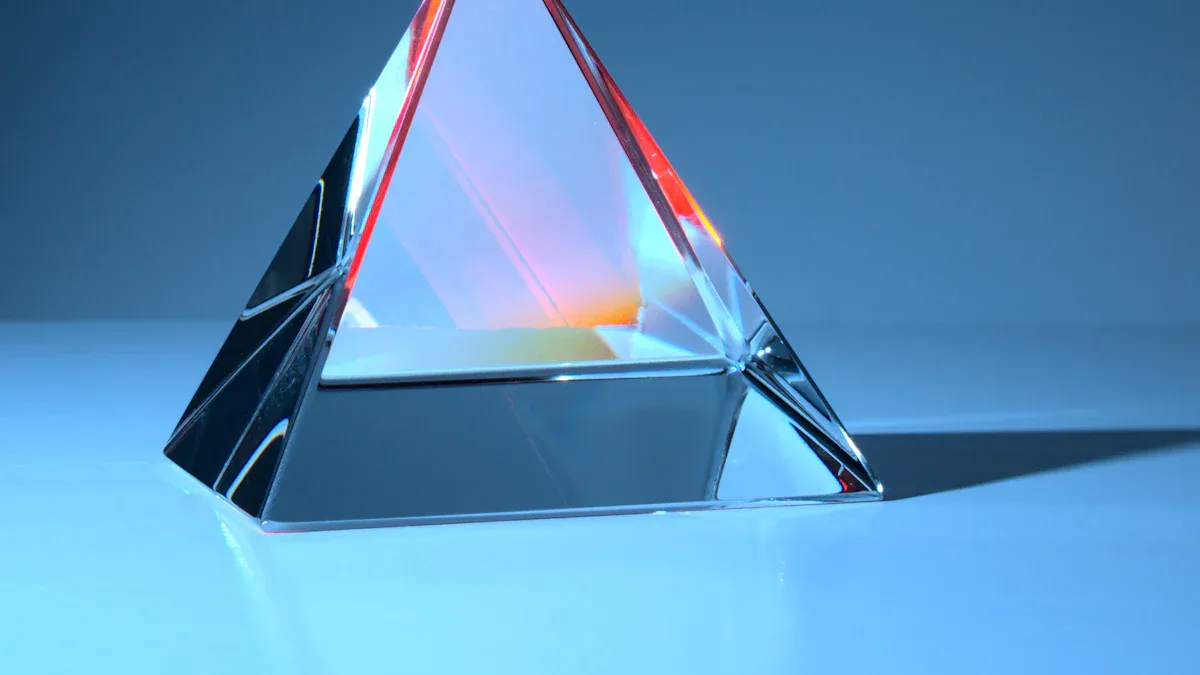

Image Source: pexels

BK7 glass is a common pick for custom optical prisms. It lets visible light pass through very well. The best range is from 350 nm to 2.0 µm. Its refractive index is 1.413 at 0.22 µm. Engineers use BK7 for lenses and domes. It is not too expensive and works well. BK7 is good with coatings and stays clear in many uses.

Fused silica can handle heat and stays stable. It lets over 90% of light through from 200 nm to 2 microns. It does not break easily from heat changes. Its expansion is low when heated. Astronomy and laser optics use fused silica a lot. It works for many light types and is very hard. Some types let even more light through. This makes it good for strong lasers.

Fused silica blocks UV light well and gives sharp images because its surface is smooth.

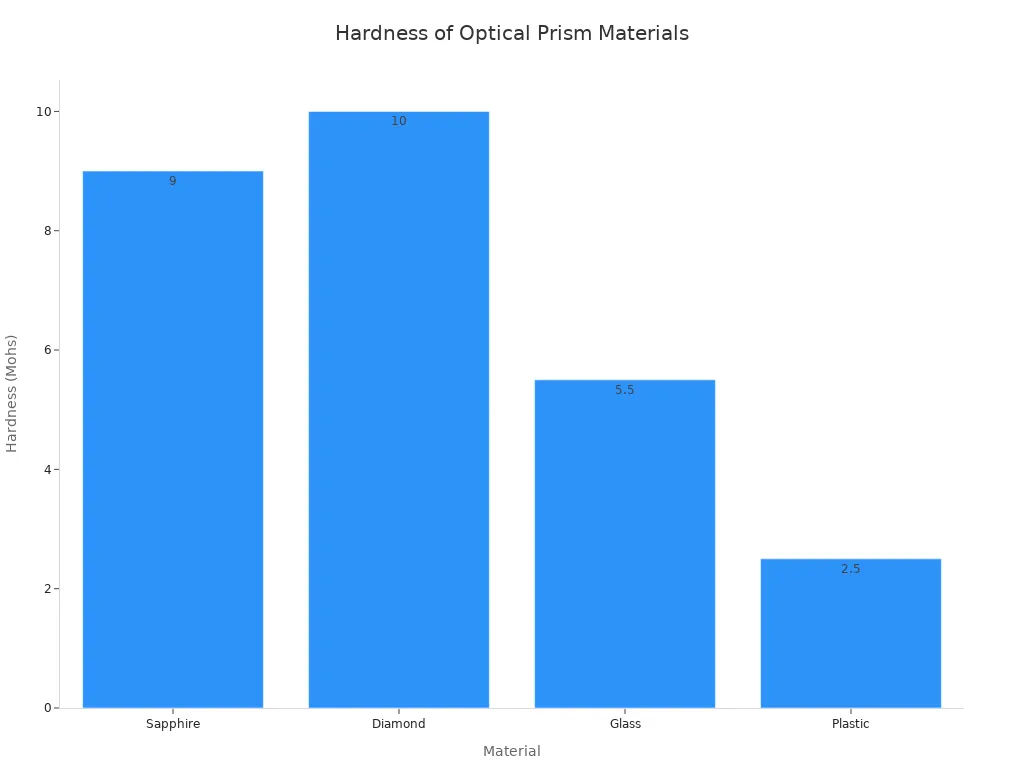

Sapphire is very hard and used in optical prisms. Its Mohs hardness is 9, just under diamond. Sapphire does not scratch easily and can handle tough places. It lets UV and IR light pass through. High-end domes and tough jobs use sapphire.

Acrylic is light and strong if hit. It is used in windows, displays, and vehicles. Acrylic is very clear but scratches more than glass. Designers use acrylic when weight is more important than being tough.

Infrared lets infrared light pass from 1.8 µm to 23 µm. Infrared cameras and defense tools use germanium. It has a high refractive index and lets lots of IR light through. Infrared works in the 3-5 and 8-12 micron ranges.

Silicon has a high refractive index of 3.422. It lets light through from 1000 nm to 10,000 nm. It can also handle up to 300,000 nm. Silicon does not expand much when heated. Its hardness is 1150 kg/mm². Many IR optical parts use silicon because it is stable and dense.

Zinc selenide is very clear in the infrared range. Its refractive index is about 2.4. It lets light through from 0.6 µm to 21 µm. CO₂ lasers and thermal cameras use ZnSe. It does not absorb much light and can handle heat well.

| Material | Key Properties | Common Use Cases |

|---|---|---|

| BK7 Glass | Not costly, lets visible light through | Lenses, domes |

| Fused Silica | Handles heat, clear from UV to IR | Astronomy, laser optics |

| Sapphire | Hard to scratch, very tough | High-end domes, tough places |

| Acrylic | Light, strong if hit | Windows, displays, fixtures |

| Infrared | Lets IR light through, high refractive index | Infrared cameras, defense tools |

| Silicon | Lets IR light through, stable | IR optical parts |

| ZnSe | Wide IR range, does not absorb much | CO₂ lasers, thermal cameras |

Each material is best for certain jobs and uses. Picking the right one helps engineers make custom optical prisms for special needs.

Engineers use four main things to compare materials. They look at optical properties, mechanical strength, cost, and if it fits the job. Each thing helps them pick the best material for the optical prism or other parts.

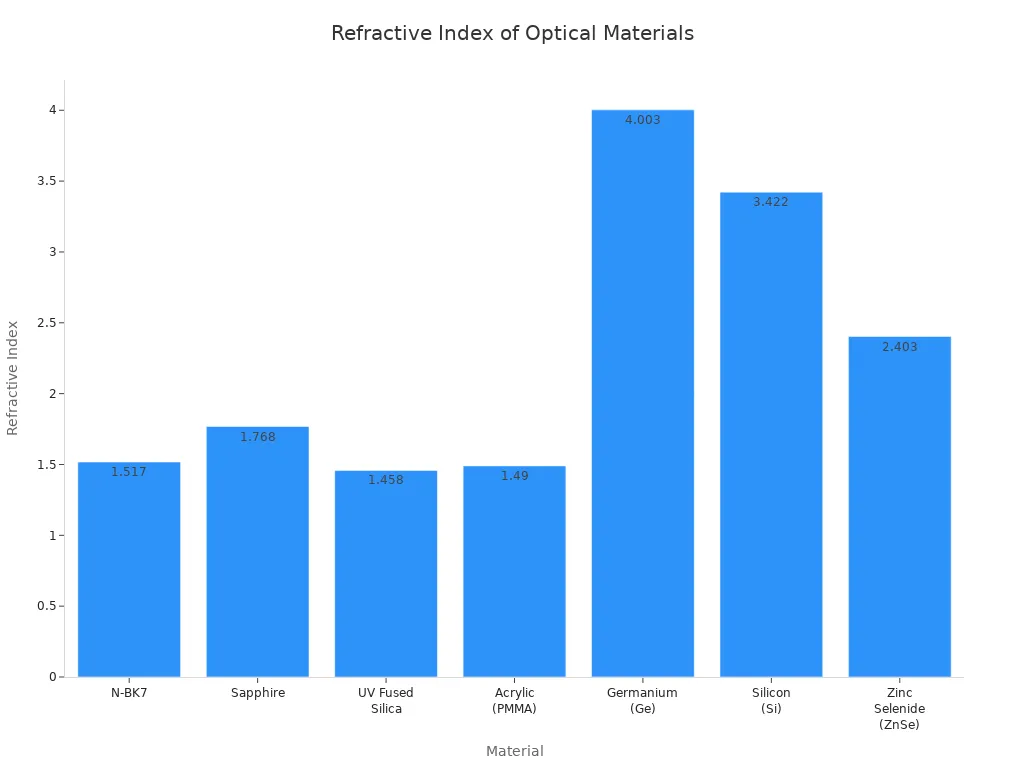

Optical properties tell how much light goes through a material. They also show how the material bends light. Transmittance means how much light passes through. Refractive index tells how much the light bends. Different materials have different numbers for these things.

| Material | Refractive Index | Transmission Range (nm) |

|---|---|---|

| N-BK7 | 1.517 | 400 - 700 |

| Sapphire | 1.768 | 2000 - 2200 |

| UV Fused Silica | 1.458 | 200 - 1000 |

| Acrylic (PMMA) | 1.49 | 400 - 700 |

| Infrared (Ge) | 4.003 | 780 - 936 |

| Silicon (Si) | 3.422 | 1150 - 1500 |

| Zinc Selenide (ZnSe) | 2.403 | 120 - 250 |

Mechanical strength means how well a material can take stress. It also means how well it handles scratches or quick temperature changes. Sapphire is very hard and does not scratch easily. Fused silica can take heat and sudden temperature changes. Acrylic is light and strong if hit but scratches more than glass.

Cost is important when picking a material for prisms. Some materials are more expensive because they are rare or hard to make. The table below shows the price range for some common materials:

| Material | Price Range (USD) | Minimum Order Quantity |

|---|---|---|

| BK7 | 1.00 - 5.00 | 10 Pieces |

| Fused Silica | 4.75 - 23.63 | N/A |

| BK7 (Laser) | 3.55 - 31.30 | N/A |

| Customized BK7 | 6.85 - 12.89 | N/A |

Application suitability means how well a material works for a job. Some materials are best for high-power lasers, UV, or IR uses. For example, zinc selenide is good for high-power IR lasers because it lets a lot of light through. Fused silica is great for UV and laser systems. Engineers choose the material that fits what their optical parts need.

Picking the right material makes sure the optical prism works well where it is used.

Image Source: unsplash

BK7 is a popular glass for optical prisms. It is very clear and lets visible light pass through well. Labs check its surface and how much light it loses. This helps make sure it works right. The table below shows how cleaning changes BK7’s surface:

| Nozzle Type | PV Value Before (nm) | PV Value After (nm) | PV Decrease (%) | RMS Value Before (nm) | RMS Value After (nm) | RMS Decrease (%) |

|---|---|---|---|---|---|---|

| Nozzle A | 318.765 | 160.135 | 49.5 | 70.586 | 15.734 | 80 |

| Nozzle B | 315.556 | 190.568 | 39.6 | 76.556 | 58.544 | 23.6 |

BK7 is liked because it is not too costly and lasts long. It works with coatings and fits many optical parts.

Fused silica stays stable when heated and does not get damaged by lasers. Scientists use it in strong lasers and space tools. It does not change shape much when it gets hot or cold. The quote below shows how special treatments help fused silica:

The results show that HF-based etching can open and smooth cracks/scratches, improving laser-induced damage threshold (LIDT) at scratches by up to >250%. Thermal annealing did heal, to some extent, cracks but the LIDT is little improved.

Fused silica is picked for tough jobs because it lets lots of light through and can take strong lasers.

Sapphire is very hard and does not react with most chemicals. It can handle very hot places and tough jobs. Some important facts are:

Maximum temperature it can take is 1900°C

Sapphire does not react with most things at room temperature.

Sapphire is tough and clear in UV and IR light. This makes it great for custom prisms in hard or careful work.

Acrylic is light and easy to shape. It lets light through well and does not get damaged by UV. The table below shows how acrylic and glass compare:

| Property | Acrylic | Glass |

|---|---|---|

| Light Transmission | Superior light transmission | Good optical clarity |

| Environmental Durability | Less susceptible to discoloration and embrittlement | May not withstand UV stability and impact resistance |

| UV Resistance | High resistance to UV energy | Susceptible to degradation under UV exposure |

| Mechanical Strength | Maintains strength over time | Can become brittle over time |

| Applications | Ideal for outdoor applications | Less suitable for outdoor use |

Acrylic is good for outdoor parts and when you need something light, even if it scratches more.

Infrared works well with infrared light. It lets light through from just under 2 to 11 microns. Here are some key points about germanium:

Infrared lets about 44% of mid-infrared light through.

At 12 microns and more, it absorbs light because of phonons.

Near 2 microns, it stops letting light through because of electronic transitions.

At 1.875 microns, it absorbs a lot, which changes the light beam.

Infrared is used for thermal cameras and infrared prism systems.

Silicon has a high refractive index and lets near and mid-infrared light through. It stays strong under heat and pressure. Engineers use silicon for IR prisms in sensors and cameras. Its hardness and density help it keep its shape and work well for a long time.

ZnSe, or zinc selenide, is great for infrared light. It lets light through easily and does not absorb much. The table below shows what is good and bad about ZnSe:

| Aspect | Description |

|---|---|

| Sensitivity to Moisture | ZnSe prisms can be hurt by water, so they need protection. |

| Chemical Environment Sensitivity | ZnSe can break down in wet air, so it needs coatings. |

| Mechanical Softness | ZnSe is soft, so it must be handled carefully and polished with care, which costs more. |

| Optical Performance | ZnSe lets lots of infrared light through, does not absorb much, and can take strong lasers. |

| Thermal Conductivity | ZnSe does not move heat well, so it can be a problem in strong lasers over 5 kW. |

ZnSe is best in safe places where water and harsh chemicals cannot reach it, so its optical performance stays high.

Picking the best material for custom optical prisms is important. Engineers check how each optical prism works in different situations. They also look at the size, shape, and how smooth the surface is. These things help them pick the right material for each use.

How flat and smooth the surface is matters a lot. Even small changes can change the image or the way light moves.

The table below compares the most used materials for custom optical prisms. It shows the main things engineers look at for performance and price.

| Material | Transmission Range (nm) | Refractive Index | Surface Flatness | Surface Quality (S&D) | Angle Tolerance | Max Size (mm) | Cost Level |

|---|---|---|---|---|---|---|---|

| BK7 | 350 – 2000 | 1.517 | λ/10 | 40/20 | ±1 arcmin | 300 | Low |

| Fused Silica | 200 – 2200 | 1.458 | λ/10 | 40/20 | ±1 arcmin | 300 | Medium |

| Sapphire | 150 – 5500 | 1.768 | λ/10 | 40/20 | ±1 arcmin | 100 | High |

| Acrylic | 400 – 1100 | 1.49 | λ/4 | 60/40 | ±2 arcmin | 300 | Low |

| Infrared | 1800 – 23000 | 4.003 | λ/4 | 60/40 | ±2 arcmin | 100 | High |

| Silicon | 1000 – 10000 | 3.422 | λ/4 | 60/40 | ±2 arcmin | 200 | Medium |

| ZnSe | 600 – 21000 | 2.4 | λ/4 | 60/40 | ±2 arcmin | 200 | High |

Engineers use these details to sort optical parts.

Most prisms are between 0.3 mm and 300 mm in size.

Smaller tolerances, like ±0.05 mm, can make things work better but cost more.

Getting the best results means controlling these details very closely. How flat the surface is and the angle tolerance are very important for clear images. The material you pick changes how the optical prism works and how much it costs.

Tip: Always pick the material and details that fit your needs. This helps custom optical prisms work their best.

High-precision optical systems need materials that are very clear and do not bend light in the wrong way. These materials must also work well over time. Engineers often pick fused silica and BK7 glass for these systems. Fused silica lets lots of light through, from UV to IR, and does not break from fast temperature changes. BK7 glass is cheaper and still works well for many uses. Sapphire is picked when the prism needs to be tough and not scratch.

These materials are used in many high-precision tools like endoscopes, headsets, cameras, sensors, LED lights, guidance tools, night vision, and special light pipes. Engineers also use different shapes and coatings, such as spheres, aspheres, freeforms, filters, mirrors, windows, beamsplitters, straight edges, cylinders, and optical coatings.

The best material depends on the light type, how well it works, where it will be used, and how much it costs.

Tip: For high-precision systems, pick materials that are very pure and made with tight controls.

Cost-sensitive projects need materials that work well but do not cost too much. BK7 glass is a top pick because it is cheap and easy to shape. Acrylic is good when you need something light and strong, like in displays or car windows.

The table below lists some low-cost materials and what they are used for:

| Material | Application |

|---|---|

| N-BK7 | General optical applications |

| Fused silica | UV applications |

| Sapphire | Extreme durability |

| Calcium fluoride | IR applications |

| Zinc selenide | IR applications |

| Specialty glasses | Unique requirements |

BK7 and acrylic help save money when making lots of parts. Fused silica costs more but is needed for UV jobs.

Some prisms must work in tough places. These places can be hot, change temperature fast, or have things that scratch or damage the prism. Fused silica and sapphire are good for these jobs. Fused silica does not break from heat or scratches. Sapphire is very hard and does not get damaged by chemicals.

| Material | Thermal Shock Resistance | Abrasion Resistance | Chemical Exposure Resistance |

|---|---|---|---|

| Fused Silica | Excellent | High | Good |

| Borosilicate | Above-average | High | Good |

| Sapphire | Good | Excellent | Excellent |

Sapphire is best if the prism might get scratched or touched by harsh chemicals. Fused silica is best if the temperature changes quickly.

Note: Always think about where the prism will be used before picking a material.

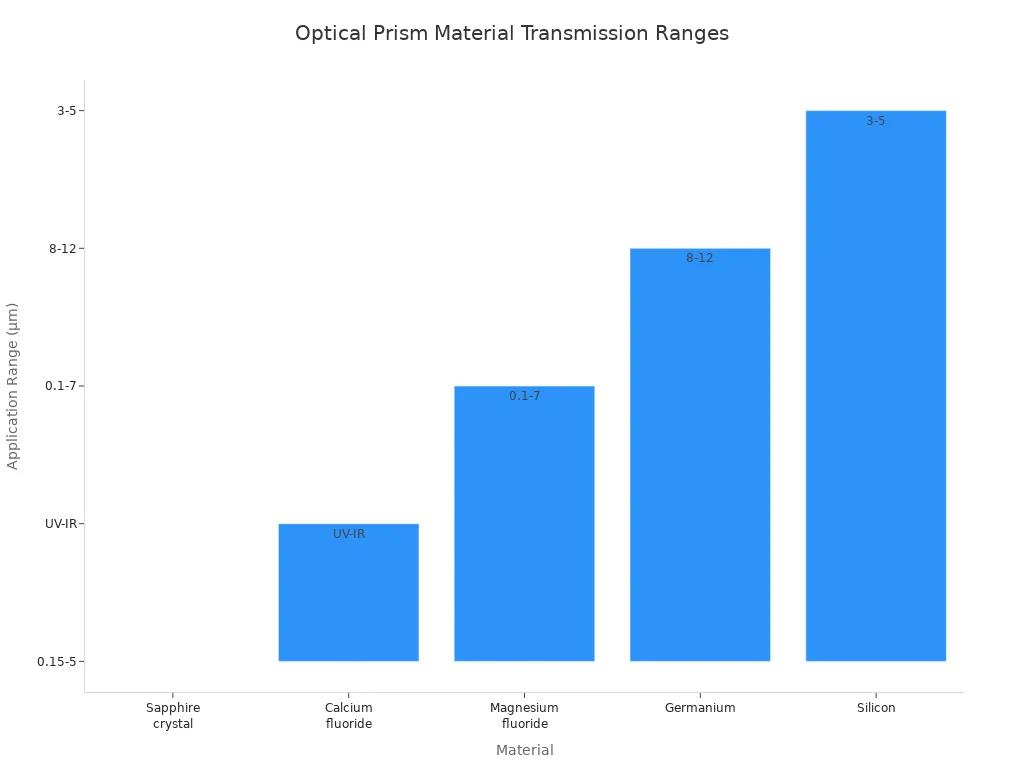

Infrared and UV jobs need materials that let certain light waves pass through. Sapphire, calcium fluoride, magnesium fluoride, germanium, and silicon are common picks. Each one works for different light ranges and has its own good points.

| Material | Application Range (µm) | Notes |

|---|---|---|

| Sapphire crystal | 0.15 to 5 | Very strong, hard to scratch, but costs more. |

| Calcium fluoride | UV to IR | Works for many uses, low refractive index, used in thermal imaging and lasers. |

| Magnesium fluoride | 0.1 to 7 | Cheaper, but needs careful handling because it is sensitive to heat. |

| Infrared | 8 to 12 | Used in night vision, does not spread light much, tough with DLC. |

| Silicon | 3 to 5 | Handles heat, used in cameras and military tools. |

Sapphire and calcium fluoride work for both UV and IR. Infrared and silicon are best for mid and far IR uses.

RGB prisms split light into red, green, and blue. These prisms need materials that keep colors clear and do not mix them up. Low dispersion glass with fluorite helps stop color mistakes. Achromatic doublets, made from crown and flint glass, fix color at two light types. Apochromatic lenses fix color at three light types.

Engineers use rgb prisms in projectors, cameras, color sensors, displays, science tools, and sorting machines. To get the best color, designers pick low dispersion glass with fluorite, achromatic doublets, or apochromatic lenses.

Rgb prisms need careful design and the right glass to split colors well. The glass choice changes how well the prism works. Good coatings help more light pass through and stop unwanted reflections. Many rgb prisms use crown and flint glass to balance cost and performance. For the best color, fluorite glass or apochromatic designs are used.

Designers should match the glass and design of rgb prisms to what the optical system needs. This gives the best color and makes sure the prism lasts.

Picking the right material for custom optical prisms is important. Each material has its own special features, strength, and price. The table below shows what you should think about:

| Factor | Description |

|---|---|

| Material Properties | Things like refractive index, how much it grows with heat, and how tough it is change how it works. |

| Availability and Cost | How easy it is to get and how much it costs matter for your project. |

| Manufacturing Considerations | Some materials are easier to shape, which can save time and money. |

| Wavelength Compatibility | The material must work with the kind of light you need. |

| Durability and Coatings | It should not get damaged easily and should work with coatings. |

Engineers need to pick a material that fits the job and the money they have. If the project is special, talking to an optical expert can help get the best outcome.

BK7 glass is used the most for optical prisms. It is very clear and strong. BK7 does not cost a lot. Many engineers pick BK7 for lab and factory work with visible light.

Acrylic prisms are good if you need something light. They are cheaper and can take a hit better than glass. But acrylic scratches easier than glass. It also does not last as long in rough places.

Infrared, silicon, and zinc selenide (ZnSe) are best for infrared light. These materials let IR light pass through well. Engineers use them in thermal cameras, sensors, and lasers.

Surface quality changes how much light gets through and how clear the image is. Good surfaces stop light from scattering and keep the image sharp. Engineers pick materials that can be polished very smooth for the best results.