close

Choose Your Site

Global

Social Media

Views: 0 Author: Site Editor Publish Time: 2025-10-24 Origin: Site

When you start ordering custom optical prisms, you need clear details and a good idea of how you will use them. Many problems can arise, such as meeting strict size limits or working with tricky shapes. Creating each prism requires careful steps and skilled hands. You should gather all your technical information, determine your budget, and establish a timeline before you consult with a manufacturer. This planning helps you avoid longer wait times and higher costs.

Make sure you know what you need for your prism. Decide on the type, material, size, and coatings. This helps you avoid mistakes in your project.

Pick a manufacturer that has a good reputation. Make sure they have experience and the right certifications. This helps you get quality custom optical prisms.

Ask for a detailed quote from the manufacturer. Compare different offers carefully. Check delivery times, payment rules, and what services are included, not just the price.

Look at the technical details and drawings before you order. This step helps you avoid expensive errors. It also makes sure you get what you want.

Talk often with your manufacturer. Clear talks and quick updates help you get better results. They also help fix problems faster.

Image Source: pexels

When you want to order custom optical prisms, you must know what you need. This helps you avoid errors and makes sure the prisms work for your project.

Pick the right prism type for your job. Each shape does something different:

Right-Angle Prism: It bends light at a 90-degree angle. You find these in cameras and periscopes.

Dispersive (Triangular) Prism: It splits white light into colors. Scientists use these in labs to study light.

Dove Prism: It turns images without flipping them. Telescopes and cameras use these for clear pictures.

Tip: Think about where you will use the prism. Scientific research, medical devices, laser systems, and aerospace tools all need special prism types.

The material you choose changes how the prism works. Here is a table with common materials and their good points:

| Material | Advantages |

|---|---|

| Glass | Clear and steady, great for tools like cameras and microscopes. |

| Quartz | Strong, handles heat changes well, good for laser systems. |

| Acrylic | Light, cheap, easy to shape, good for school tools and low-cost devices. |

Pick a material with a high refractive index, like glass or quartz, for better results.

You need to pick the size and accuracy of your prism. The table below shows what is normal in the industry:

| Specification | Base | Precision | High Precision |

|---|---|---|---|

| Angular Tolerance | 6 arc min | 1 arc min | 15 arc sec |

| Bevel | 0.2 mm | 0.1 mm | 0.02 mm |

| Surface Quality | 80/50 | 60/40 | 20/10 |

| Surface Irregularity | 1 wave | λ/4 | λ/20 |

| Surface Finish | 50 Å rms | 20 Å rms | 5 Å rms |

Note: If you want tighter tolerances, the prisms will be better but may cost more and take longer to make.

Coatings help your prism work better with light. Here are some common coatings and what they do:

| Coating Material | Key Properties | Applications |

|---|---|---|

| Silicon dioxide (SiO2) | Lasts long, very clear, good refractive index | Optical coatings for clear and bright images |

| Titanium dioxide (TiO2) | Very strong, high refractive index, cuts down glare | Eyeglasses, camera lenses |

| Magnesium fluoride (MgF2) | Very tough, low absorption, lets more light through | Laser mirrors, camera lenses |

| Fluorides | Very tough, stands up to weather, cuts reflection | Car windows |

| Infrared (Ge) | Very hard, low absorption, great anti-reflective ability | Camera lenses, eyeglasses |

| Metal coatings | Very strong, reflects light well over many colors | Solar panels, eyeglasses |

| Dielectric coatings | Makes images clearer, changes how light moves | Cameras, TVs, electronics |

Anti-reflective coatings are popular because they lower light loss and glare.

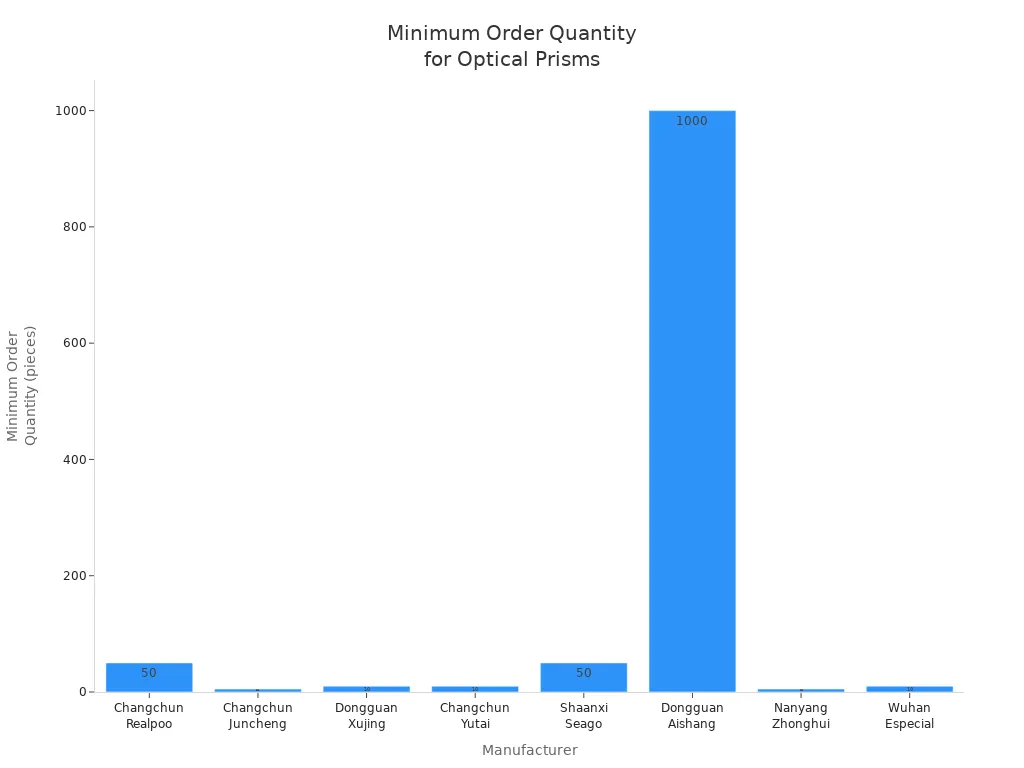

You should know how many prisms you need. Manufacturers have different minimum order amounts. The chart below shows how these numbers can change:

Some companies let you order as few as 5 pieces. Others may want you to buy 50 or more. Always ask your manufacturer before you order.

Remember: If you know your needs, ordering custom optical prisms is easier and you get better results for your project.

Picking the right manufacturer is very important. You want someone who makes good prisms and helps you from start to finish.

Find a manufacturer with lots of experience making optical prisms. They know how prism quality and details affect your project. These companies help you get the best results. For example, PFG Optics makes high-precision custom prisms. Tower Optical creates custom prisms for many uses and uses special tools. Precision Optical gives certified custom prism solutions. LaCroix Precision Optics works on high-precision prism assemblies.

Tip: Pick a manufacturer who has done projects like yours. This helps you get better results.

Certifications show a manufacturer follows strict rules for quality. The most important ones are:

| Certification | Importance |

|---|---|

| AS9100 | Makes sure quality is good for aerospace manufacturing. |

| ISO 9001 | Shows quality management in many industries. |

| ITAR | Follows rules for defense products. |

A certified manufacturer gives you trust in their work and products.

Check what the manufacturer can do. Top suppliers offer:

Precision work with tight tolerances and smooth finishes.

Many materials, like acrylic, fused quartz, and calcium fluoride.

Custom work for different prism types, like Dove and roof prisms.

Special coatings, such as dielectric or metal, for unique needs.

Fast delivery if you need your order quickly.

Companies like Edmund Optics, Avantier Inc., and Knight Optical offer these options.

Good customer support makes ordering easier. You want a manufacturer who answers fast and helps solve problems. Look for companies with high on-time delivery and good reviews. Some, like Optimax and Esco Optics, are known for great service and support.

| Criteria | Description |

|---|---|

| Quality Verification | Check how well they perform and what customers say. |

| Performance Indicators | Look at delivery times and how fast they reply. |

| Factory Audits | Make sure they have strong checks for quality. |

| Optical Testing | Ask about accuracy and how tough the coatings are. |

Note: Good support and clear talks help you avoid mistakes and delays.

To order custom optical prisms, you first need to ask for a quote. You do this by sending a request for quotation (RFQ) to the manufacturers you pick. This helps you learn the price and how long your project will take. Get all your important details ready before you send your RFQ. Giving clear information helps the manufacturer know what you want and answer fast.

Here is a table that shows what you should put in your RFQ:

| Required Information | Description |

|---|---|

| Company Name | Name of your company |

| Contact Name | Your name or the main contact person |

| Phone Number | A phone number for quick communication |

| Email Address | An email address for updates and questions |

| RFQ Number | A reference number for your request |

| Part Number | The specific part number for your prism |

| Glass Type | The type of glass or material you need |

| Part Shape | The shape of the prism (like rectangular or ellipse) |

| Dimensions and Tolerances | Size, thickness, and how exact the measurements are |

| Other Notes | Any special needs or extra information |

Tip: Check your details before you send your RFQ. If your information is clear and complete, you will have fewer mistakes and delays.

After you send your RFQ, you will get quotes from different companies. Each quote may look different, so you need to check them closely. Do not just look at the price. You should also check how long delivery takes, how you pay, and what comes with the offer.

You can use this checklist to help you compare quotes:

Price for each prism and total cost

Delivery time and shipping choices

Payment rules (like deposit or full payment)

Services included (such as coatings or testing)

Minimum order amount

Warranty or help after you get your order

If you do not understand something, ask the manufacturer for more information. Talking clearly helps you avoid problems later.

Note: Do not pick only by price. Sometimes a higher price means better quality or faster shipping.

Before you order, you need to check the technical specs and drawings. This step makes sure the manufacturer knows exactly what you want. Checking carefully helps you avoid expensive mistakes.

Here is a table that shows the best ways to review specs and drawings:

| Parameter Type | Description |

|---|---|

| Dimensional Parameters | Check the size, shape, and any curves or angles. |

| Tolerance Specifications | Make sure the allowed differences from the main size are clear. |

| Surface Quality | Look for details about scratches, roughness, and other surface features. |

| Coating Specifications | Review the type of coating, what it is made of, and how it affects light. |

| Standardized Notation | Use clear symbols and notes, like ISO 10110, for easy understanding. |

| Quality Assurance | Confirm the specs meet international standards for optical parts. |

| Global Adoption | Make sure the specs follow common industry rules for better results and easier communication. |

Callout: Always ask for a final drawing or spec sheet before you say yes to the order. This step keeps you safe from mistakes and helps you get the right product.

If you follow these steps, ordering custom optical prisms is easier and more dependable. You will get the prisms you need, on time and with the right quality.

When you reach the payment stage, you need to understand the terms each manufacturer offers. Payment terms tell you when and how to pay for your order. Some companies give you a discount if you pay early. Others expect payment within a set number of days after you get the invoice. Here is a table with examples from well-known manufacturers:

| Manufacturer | Payment Terms |

|---|---|

| Ross Optical | 2% discount if paid within 10 days, net 30 days. Late charge of 2% per month after 30 days. |

| IOS Optics | Standard payment terms: Net 30. |

| Optometrics | Payment terms not specified in detail. |

Tip: Always ask about late fees or discounts before you agree to the payment terms. This helps you avoid extra costs.

Before you finish ordering custom optical prisms, you should review the contract or purchase agreement. The contract lists what you and the manufacturer must do. Check the details about product specs, delivery dates, payment rules, and what happens if something goes wrong. Make sure the contract matches the quote and your final requirements. If you see unclear points, ask the manufacturer to explain. You protect yourself by reading every part of the contract.

Review product specifications and quantities.

Confirm delivery schedule and shipping method.

Check warranty and return policies.

Make sure payment terms match your agreement.

Note: Careful contract review helps you avoid misunderstandings and keeps your project on track.

After you place your order, you want to know where your prisms are and when they will arrive. Most manufacturers give you an order number or tracking link. You can use this to follow your shipment. Some companies send email updates at each step. If you have questions, contact customer support for updates. Tracking your order helps you plan for the next steps in your project.

Callout: Save your order number and tracking details. Quick access to this information makes it easier to solve any delivery issues.

Image Source: unsplash

You want your custom optical prisms to be high quality. Manufacturers use different ways to check for quality. They test each prism while making it and after it is done. These tests check if the size is right, if the prism works well, and if it is strong. Special tools like interferometry and non-contact 3D profiling help find tiny problems. Before the prisms leave the factory, a final check makes sure they meet your needs.

Here are some common ways to inspect prisms:

| Inspection Technique | Description |

|---|---|

| Optical Prism Testing | Checks the prism by seeing how light goes through it. |

| Light Interaction Analysis | Finds cracks or holes by watching how light bends or spreads. |

| Advanced Imaging Equipment | Uses special cameras to find even very small problems. |

Tip: Ask your manufacturer how they check the prisms. This helps you know how they keep the quality high.

After checking, you get test reports with your order. These reports show your prisms meet the promised standards. You can use these papers to check quality and find any problems.

Here are the kinds of reports you might get:

| Type of Report | Description |

|---|---|

| Inspection Reports | Lists the quality checks done on your prisms. |

| Interferograms | Shows pictures of wavefront errors. |

| Certifications | Proves your prisms meet industry standards. |

| 100% Inspection | Confirms every prism was checked. |

Note: Keep these reports in your files. They help if you need to fix problems later.

You want your prisms to arrive on time. How long it takes can change with each order. New orders usually take about 4 to 6 weeks. Repeat orders can come in as little as 2 weeks. The time depends on how hard your prisms are to make, what materials you pick, and how many you order.

Most new orders take 4–6 weeks to arrive.

Repeat orders can take only 2 weeks.

Delivery depends on design, material, order size, and assembly.

Callout: Plan your project with these delivery times in mind. Planning early helps you avoid waiting longer.

You can feel sure about ordering custom optical prisms if you follow each step. Talking clearly and checking details helps you stop mistakes. Try these ways to get good quality and fast delivery:

| Strategy | Description |

|---|---|

| Project Planning | Make a schedule and watch each step as you go. |

| Quality Assurance | Check each part to find problems early. |

| Team Coordination | Work together to fix things fast. |

If you have a good relationship with your manufacturer, you get faster help, better answers, and results you can trust. Many people like when companies talk well, deliver quickly, and make great products.

You must tell the manufacturer the prism type, material, size, tolerances, coatings, and quantity. You also need to explain how you will use the prism. Giving clear details helps the manufacturer know what you want. This way, you get the right product for your project.

Most orders arrive in 4 to 6 weeks. If you order again, it might only take 2 weeks. The time depends on the design, material, and how many you order. Always ask the manufacturer when your prisms will arrive.

Yes, some companies let you order as few as 5 prisms. Other companies may want you to buy at least 50. You should always check the minimum order before you ask for prisms.

Tell your manufacturer right away if there is a problem. Show them the inspection reports and explain what is wrong. Most companies will help you fix the issue. They may offer a replacement or make changes if the prism is not what you ordered.

Special coatings help your prism work better by cutting glare or making it stronger. Talk to the manufacturer about how you will use the prism. They can help you pick the best coating for your needs.