close

Choose Your Site

Global

Social Media

Views: 0 Author: Site Editor Publish Time: 2025-11-11 Origin: Site

Looking for the top custom optical prism suppliers? Choosing the right company is crucial for various projects, including aerospace, healthcare, and telecommunications. Precision and customization can significantly impact outcomes. For instance, custom prisms are essential for controlling laser beams in surgical procedures, enhancing patient safety. Advanced CNC machines enable these suppliers to meet precise specifications.

Band Optics employs highly accurate tools for medical, laser, and aerospace applications.

Suppliers with AS9100 and ISO 9001 certifications demonstrate strong quality assurance.

As more high-tech industries require prisms, designs continue to evolve and improve.

| Certification | Importance |

|---|---|

| AS9100 | Quality for aerospace manufacturing |

| ISO 9001 | Quality management for industries |

| ITAR | Defense product compliance |

Utilize this guide to evaluate your options and select the best among the top custom optical prism suppliers for your needs.

Picking the best custom optical prism supplier is important for work in aerospace, healthcare, and telecommunications.

Find suppliers who have quality certificates like AS9100 and ISO 9001. These certificates show they follow high standards.

Customization lets you choose materials, shapes, and coatings that match what you need.

Experience is important. Suppliers who have worked longer often give better quality and service.

Quick lead times and helpful customer support help your projects stay on schedule and go well.

Many companies are top custom optical prism suppliers. They help aerospace, medical, and telecom industries. Each supplier has special skills and tools. Some make lots of products fast. Others create custom parts for tough jobs.

Here’s a quick look at some well-known suppliers:

| Supplier Name | Description | Location | Contact Number |

|---|---|---|---|

| Corning Tropel | Makes custom optical modules and parts. | Fairport, New York, US | (585) 388-3401 |

| Edmund Optics Inc. | Big company for optics and photonics. | Barrington, New Jersey, US | (800) 363-1992 |

| ER Precision Optical Corp. | Makes optics for mid- and long-wave systems. | Apopka, Florida, US | (407) 292-5395 |

| Esco Optics | Sells many optical parts and services. | Midland, Ontario, Canada | N/A |

| Optimax Systems Inc. | Makes high-quality precision optical parts. | Ontario, New York, US | (585) 265-1020 |

| Band Optics | Offers advanced custom optical solutions for many industries. | China | N/A |

Top suppliers use advanced ways to make products. They buy precise machines and check quality. Many have ISO 9001 or AS9100 certificates. This means they follow high standards. Some, like Band Optics, have over 15 years of experience. They help medical, laser, semiconductor, and aerospace clients.

Suppliers with good quality checks and fast prototyping help customers finish projects quickly and handle tough needs.

Suppliers sell many kinds of optical prisms and parts. These include right-angle prisms, corner cubes, roof prisms, and dispersion prisms. Some also sell lenses, filters, and windows. Product sizes go from tiny microprisms to big parts up to 100 mm.

| Product Category | Description |

|---|---|

| Right-angle prisms | Used to reflect and bend light. |

| Corner cubes | Bounce light at right angles. |

| Roof prisms | Fix images in binoculars and other tools. |

| Dove prisms | Turn images in optical setups. |

| Penta prisms | Bend light in surveying tools. |

| Dispersion prisms | Split light into different colors. |

| Wedges | Make special optical effects by bending light. |

| Dimensions | Sizes go from 2.00 mm to 100.00 mm. |

Band Optics is great at making custom optical prisms. The company has ISO 9001:2015 certification and over 15 years of experience. Band Optics sells many products like prisms, lenses, filters, and windows. They use special materials like BK7 Grade A optical glass and Corning Fused Silica.

Customers can ask for fast prototypes and custom solutions. Band Optics helps medical, laser, semiconductor, and aerospace industries. Their team uses advanced tools for tight size control, anti-reflective coatings, and strong bonding. They also give detailed test reports for custom cemented prisms and microprismatic arrays.

Band Optics helps clients get high performance and reliability in their optical systems.

Top custom optical prism suppliers help many kinds of companies. They work with defense, electronics, engineering, and medical groups. Some also help universities and research centers. Their products are used in lighting, oil and gas, and tools for measuring things.

| Industry |

|---|

| Defence & Aerospace |

| Electronics & Optoelectronics |

| Engineering & Industrial Manufacturing |

| Entertainment & Design Lighting |

| Instrumentation |

| Medical |

| Oil & Gas |

| University & Research Centers |

Suppliers come from different places. Each one has special skills and products. Some make lots of prisms at once. Others make custom prisms for special jobs.

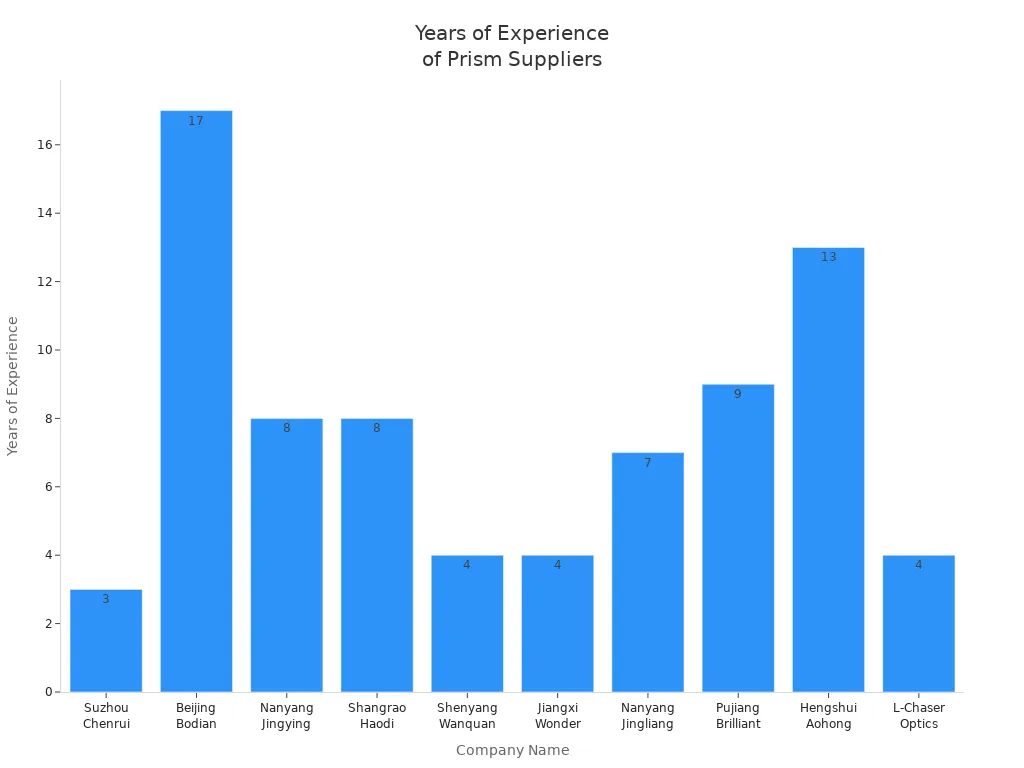

Having more experience helps suppliers do better work. Companies with more years in business often have better results. Some have worked for over 15 years. Others are new and bring new ideas. The table shows how long each company has made optics.

| Company Name | Years of Experience |

|---|---|

| Suzhou Chenrui Optoelectronic Technology | 3 |

| Beijing Bodian Optical Technology | 17 |

| Nanyang Jingying Trade | 8 |

| Shangrao Haodi Imp & Exp Trading | 8 |

| Shenyang Wanquan Photoelectric Technology | 4 |

| Jiangxi Wonder Survey | 4 |

| Nanyang Jingliang Photoelectric | 7 |

| Pujiang Brilliant Crystal | 9 |

| Hengshui Aohong Technology | 13 |

| L-Chaser Optics | 4 |

Suppliers with more years know how to check quality and deliver fast. They can fix problems and meet hard needs.

Suppliers sell many kinds of optical prisms. Some make right-angle prisms, corner cubes, and roof prisms. Others make special shapes for unique uses. Prisms can be tiny or very big for machines.

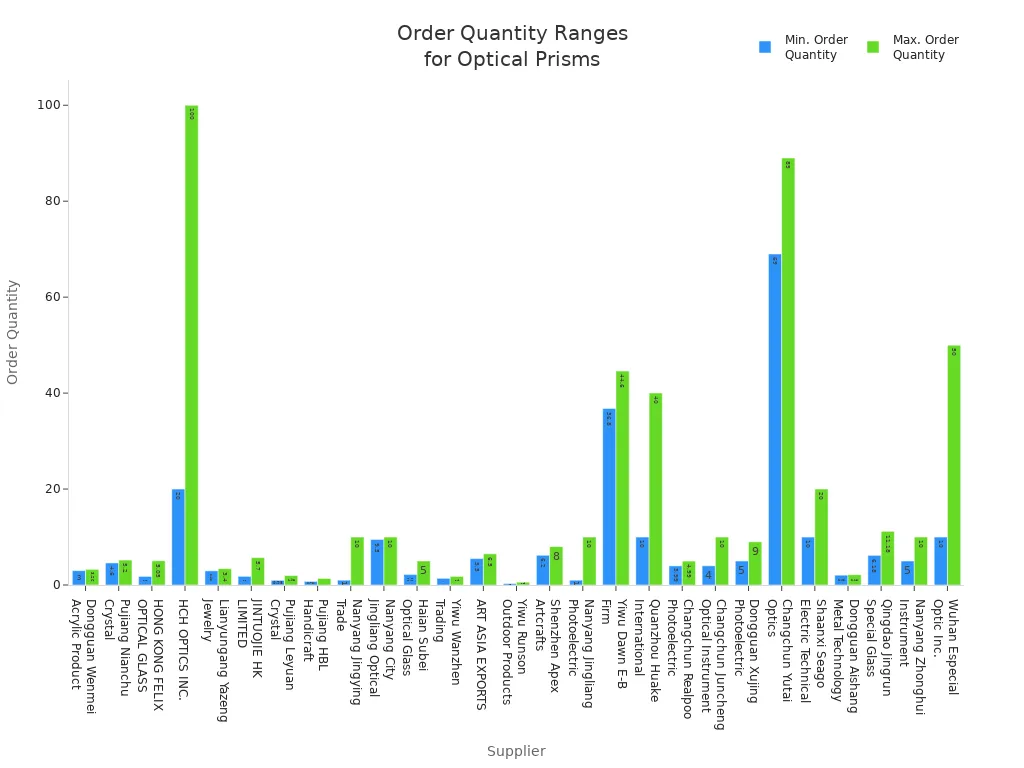

You can order just one prism or many. Some suppliers take small orders. Others fill big orders for factories. The table shows the smallest and biggest order sizes.

| Supplier | Product Description | Min. Order Quantity | Max. Order Quantity |

|---|---|---|---|

| Dongguan Wenmei Acrylic Product Co., Ltd. | High-End Customizable Transparent Acrylic Geometric Prism Trophy Medals & Plaques | 3 | 3.26 |

| Pujiang Nianchu Crystal Co., Ltd. | 3D Classic Design Multifaceted Round Glass Prism Crystal Paperweight With Custom Logo | 4.60 | 5.20 |

| HONG KONG FELIX OPTICAL GLASS CO., LIMITED | Manufacturer Custom 60 Degree Optical Prism Optical Bk7 Glass Triangle Dispersion Equilateral Triangular Prism | 1.78 | 5.05 |

| HCH OPTICS INC. | Customized Triangular Prism Reflective Prisma Optical Glass Right Angle Prism | 20 | 100 |

| Lianyungang Yazeng Jewelry Co., Ltd. | Wholesale OEM Custom K9 Window Pendant Natural Crystal Sun Catcher Quartz Crafts Stone Dream Prism Crystal Decor and Suncatchers | 2.95 | 3.40 |

Suppliers let customers pick custom options. They use special materials like BK7 glass and fused silica. Some add coatings to make prisms work better. Customers can choose shapes, sizes, and finishes. Suppliers help with design and testing. They give reports to show the prisms are good and accurate.

Many suppliers work with customers to make special solutions. They help with medical, aerospace, and research projects. Customization lets companies get what they need for their work.

Image Source: unsplash

Top custom optical prism suppliers have many features. They make prisms in lots of shapes and sizes. Some companies make many prisms at once. Others make small orders for special needs. Many use advanced machines for very exact work. They can make new designs quickly. Customers can pick suppliers who use special materials and coatings.

Each supplier is special in its own way. Some have worked for more than 15 years. They help aerospace, medical, and research companies. Others deliver orders very fast or take small orders. Some give detailed test reports with every order. Many have certificates to show they care about quality. Some help with design and testing so customers get the right prism.

Suppliers who help with custom designs and check quality are often the best choice for hard projects.

Suppliers let customers pick many custom features. The table below shows the most common choices:

| Customization Feature | Description |

|---|---|

| Material | Optical glass K9 or other custom materials |

| Dimensions | Custom length, width, and height |

| Angle | Custom right angle (90°) or other angles |

| Coating | Optional anti-reflective or special coatings |

| Surface Quality | Standard or custom (like scratch-dig) |

| Surface Flatness | Standard or custom (like λ/4, λ/10) |

| Surface Accuracy | Standard or custom (like λ/4, λ/10) |

| Clear Aperture | Custom size for best light transmission |

These choices help customers get prisms that fit their needs.

Quality is very important for optical prisms. The best suppliers follow strict rules and test their products in many ways. Here is a table of common certificates and tests:

| Certification/Testing Method | Description |

|---|---|

| DOD and ASTM specifications | Meet Department of Defense and ASTM rules |

| MIL-PRF-13830B and ISO 10110 | Follow military and international standards |

| Environmental stress and screening | Test for durability in tough conditions |

| Mechanical shock and vibration | Check for strength against shocks |

| Thermal and humidity testing | Test for heat and moisture resistance |

| Abrasion and durability testing | Check for wear and long life |

| Laser damage certification | Prove resistance to laser damage |

These rules help make sure prisms work well anywhere.

Image Source: pexels

Each project needs different things. Before you pick a supplier, think about what your project needs most. Here are some things to keep in mind:

Material Choice: Glass and quartz are best for jobs that need high accuracy. Acrylic works well for easy tasks.

Shape and Design: The prism’s shape changes how it bends or splits light.

Optical Needs: The kind of light and the angle it enters the prism are important.

Application Needs: Some prisms are better for medical imaging. Others work well for laser tools.

Optical Performance: High performance means the prism lets more light through and gives better signals.

Tip: Write down your main project goals before you talk to any supplier.

Suppliers with more experience do a better job. Companies that have worked longer know how to fix hard problems. They learn what works and what does not. Customers feel happier with suppliers who have a good history. These suppliers know both the technical parts and what customers want.

Quality is very important for optical prisms. Top suppliers use strong quality systems like ISO 9001. This helps make sure every prism is made well. Some companies use special tools like Zygo Interferometers to check the prism’s shape and surface. They also add coatings to help the prism work better.

Getting products fast helps projects finish on time. Lead times can be different for each supplier. Here is a table showing what some suppliers offer:

| Supplier | Sampling Lead Time | Mass Production Lead Time |

|---|---|---|

| Nonic Custom Optics | 1-2 weeks | 1-2 months (1000-2000 pcs) |

| PGO Online | 48 hours (express) | - |

| Luximprint | 8-10 business days | - |

Good customer support makes things easier. Top suppliers help with cutting and shaping materials. They add coatings and build custom assemblies. They check quality to make sure every order is right. Good support means someone is always ready to help or answer questions.

Picking from the top custom optical prism suppliers is easier when you match your needs with what they offer.

The top custom optical prism suppliers have lots of experience. They make high-quality products and offer custom solutions. Readers can look at tables and tips to find the best supplier. The next step is picking materials and checking how things are made. You also need to look at quality checks:

| Step | Description |

|---|---|

| Selection of Materials | Picking the right materials helps the prism work well. |

| Fabrication Technologies | Using new machines helps cut, grind, and polish with care. |

| Quality Assurance and Testing | Careful testing makes sure parts are accurate and work right. |

| Final Inspection and Delivery | Checking parts one last time before shipping keeps standards high. |

| Post-Delivery Support | Help after delivery makes sure parts work and fixes future problems. |

Many customers ask for help with technical questions. They want to know about sizes, how prisms are made, and coating choices:

| Topic | Description |

|---|---|

| Specifications | Exact details for prisms, like size and what they are made of. |

| Manufacturing Capabilities | How the company makes prisms and what machines they use. |

| Optical Coating Options | Different coatings can make prisms work better. |

Talking to a supplier can help you understand your project and costs. This helps you get the best results for your needs.

Custom optical prisms are used in many fields. They help with medical imaging and aerospace navigation. Laser systems need them too. Telecommunications use prisms for signals. Research labs and universities use them for tests and experiments.

Suppliers check prisms with special tools. They use interferometers and inspection systems. Many companies follow ISO 9001 or AS9100 rules. They check the surface, coating, and do a final inspection.

Tip: Always ask for a test report before you buy.

Yes, customers can pick custom coatings and shapes. Suppliers offer anti-reflective coatings and special angles. They help design prisms for each project.

Lead times change by supplier and order size. Small samples can ship in a few days. Big orders may take weeks. Fast prototyping helps deliver quicker.

| Order Type | Typical Lead Time |

|---|---|

| Sample | 1-2 weeks |

| Mass Production | 1-2 months |