close

Choose Your Site

Global

Social Media

Views: 0 Author: Site Editor Publish Time: 2025-11-07 Origin: Site

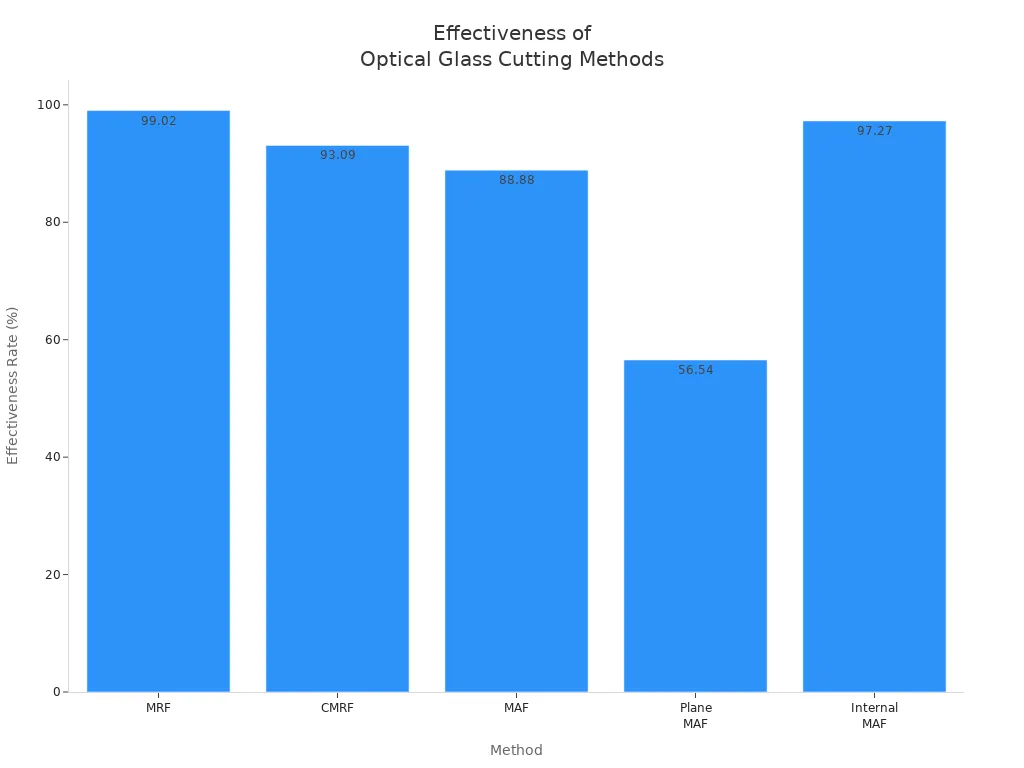

Controlling how smooth the surface is in Optical Glass Cutting is very important. It helps get good optical performance. Makers use different ways to keep the surface nice. The best ways are Magnetorheological Finishing (MRF) and Internal Magnetic-Field-Assisted Finishing (Internal MAF). These methods work well and have effectiveness rates over 97%.

| Method | Effectiveness Rate (%) |

|---|---|

| MRF | 99.02 |

| CMRF | 93.09 |

| MAF | 88.88 |

| Plane MAF | 56.54 |

| Internal MAF | 97.27 |

New cutting and polishing tools, like laser cutting and CNC machining, make things better and faster. These new tools help make exact parts and allow for making many at once.

It is important to control surface finish for good optical performance. Smooth surfaces help lenses work better and scatter less light.

New cutting methods like laser cutting and CNC machining make optical glass more precise and faster to produce.

Measuring surface roughness well helps find problems early. This makes sure optical parts last long and stay high quality.

Advanced polishing methods like magnetic-field-assisted polishing make surfaces very smooth and do it fast. This helps when making many parts at once.

Keeping tools clean and checking for wear helps polishing work better. This leads to better surface quality in optical glass pieces.

Surface finish control is very important for optical glass parts. When makers focus on surface finish, lenses become more accurate in shape. Experts check this by measuring surface roughness, surface error, and waviness. These things change how well a lens works in an optical system. Researchers found that mistakes with fixtures and worn tools can change surface accuracy. Studies by Kong et al. and Karl Zeiss Company used math to show how surface shape connects to optical performance.

Surface roughness makes light scatter, which lowers image contrast and causes distortion.

Tiny features on the surface reflect light in many ways, which reduces image quality.

Uneven surfaces change the phase of light, which can hurt resolution and focus.

Makers use new technologies to fix these problems. Ultrasonic vibration-assisted slow tool servo turning (UVSTS) helps make machining faster and more exact. UVSTS can reach surface roughness as low as 1 nm Sa, so results are very precise without extra steps.

Surface finish control also matters when making lots of optical glass parts. Good surfaces lower scattering and make image contrast better, which helps optical performance. Stricter scratch-dig rules make systems work better, especially for strong lasers. Lower Ra values help stop scattering and let more light pass through. Filters made with strict rules can last over 10,000 hours and still work well.

Bad surface finish makes coatings fail faster and means more repairs.

Production can slow down in places like semiconductor factories if surface quality drops.

| Challenge | Description | Current Technology Addressing Challenge |

|---|---|---|

| High Precision | Hard-brittle glass makes precision hard. | UVSTS makes work faster and more exact. |

| Crack Formation | Cracks can happen during cutting. | UVSTS helps predict and control cracks. |

| Surface Quality | Old methods may not get good quality fast. | UVSTS gets 1 nm Sa roughness without extra steps. |

Makers must control surface finish to keep up with mass production and keep quality high. This control makes sure every optical glass part meets strict rules and works well in its job.

Engineers check how smooth or rough optical glass is. This is called surface roughness measurement. Surface roughness changes how light moves in glass. It also affects how well the glass works in devices. ISO 21920 gives rules for measuring surface roughness. These rules have three parts: surface finish, terms and parameters, and specification operators. This helps engineers talk clearly about what they want.

There are three main ways to measure surface roughness. Each way shows something different about the surface. The table below explains these ways:

| Parameter | Description | Typical Application Context |

|---|---|---|

| Ra | Measures the average height of surface bumps. | Used in drawings and general surface checks. |

| Rq | Shows the standard deviation of surface heights. | Helps find big problems in surface texture. |

| Rz | Calculates the average of the five highest peaks and five lowest valleys. | Good for sealing surfaces and wear checks. |

Ra is simple to use, but it only looks at the surface in two dimensions. It does not show the whole shape of the surface. Rq and Rz give more details about the roughness. Using 3D parameters helps engineers see the surface better and know how it will work.

Tip: Measuring surface roughness helps find problems early. It keeps optical glass working well for a long time.

Profilometers and other tools help measure surface roughness. These tools check the shape of surfaces. They make sure products meet strict rules. There are two main types of profilometers: contact and non-contact.

Contact profilometers use a stylus to touch the surface. They are very accurate, but can scratch soft glass.

Non-contact profilometers use lasers or light to scan the surface. They do not touch the glass, so they keep it safe. These tools are fast and can check many surfaces.

The table below compares different tools:

| Tool Type | Measurement Capabilities |

|---|---|

| Optical Profilometers | Non-contact measurement of surface profiles, including surface elevation as a function of lateral coordinates. Can detect surface form, roughness, and isolated defects. |

| Surface Metrology Tools | Determines roughness, contour, and other surface parameters. Non-contact and adaptable to various measuring tasks. Evaluates geometries and roughness according to ISO standards. |

| 3D Optical Profilers | Provides accurate 3D optical metrology independent of surface characteristics. Suitable for complex geometries and compliance with ISO norms. |

New tools for measuring surface roughness help makers find problems early. They help keep products within the right limits. These tools work for laser mirrors, prisms, and glass flats. They are also used for research and checking quality. Non-contact ways to measure roughness are safe and reliable. But they can cost more and may not work well on very rough surfaces.

Note: Good surface roughness measurement is important for coatings and optical devices. It helps products last longer and work better.

Image Source: pexels

Mechanical cutting uses special tools. These tools include diamond blades and endless diamond wire saws. They help shape optical glass parts with high accuracy. Diamond blades can cut hard glass-ceramics. But this process often leaves damage under the surface. Endless diamond wire saws help the tools last longer. They also keep the surface finish steady. Ultra-precision turning can make parts more exact. Sometimes, the edges get worse during machining.

Glass-ceramics are strong but break easily, so they are hard to machine.

Precision grinding makes surfaces very accurate, but some damage stays under the surface.

Ultra-precision turning has problems with edges getting worse.

| Evidence Type | Description |

|---|---|

| Surface Roughness | Surface roughness changes with cutting style, material, and tool settings. |

| Defect Rates | Faster cutting and deeper cuts make more defects and lower quality. |

| Prediction Models | Engineers use models to guess surface roughness from how they process parts. |

How well glass-ceramic optics work depends on the finish.

Removing brittle parts can hurt the surface and the area below.

Regular diamond turning cannot always remove fused silica smoothly.

Diamond wire saw machines can cut down polishing time by 30–50%. This saves money and makes work faster. New cutting methods also lower damage from force and heat. This leads to better surfaces and quicker production.

Tip: Picking the best mechanical cutting method helps control surface finish and defects in optical glass cutting.

Water jet cutting uses strong water streams to cut glass. This way makes smooth and exact cuts. It helps the surface finish look better. Water jet cutting leaves tiny kerfs, so there is little waste. The process also gives better size accuracy. It works well for jobs that do not need extra finishing.

Hot air jet cutting uses hot air to slice glass. This can help stop tiny cracks and keep edges neat. Both water jet and hot air jet cutting help make better edges and surfaces. This is important when making lots of optical glass parts.

Water jet cutting makes glass parts look nicer.

Small kerfs mean less waste and better accuracy.

Many companies use water jet cutting for parts that do not need more finishing.

Note: Water jet and hot air jet cutting help keep good surface finish and size accuracy in optical glass cutting.

Laser cutting uses focused light beams to cut glass. The beam touches the glass for only a short time. This stops the glass from bending or cracking. Laser cutting makes smooth edges and fewer tiny cracks or defects. Unlike older ways, laser cutting does not need sanding after cutting.

Aluminosilicate glass cut with a ns-355nm laser chips about 45.7µm.

A ps-1064nm laser makes chips smaller than 5µm.

An fs-515nm laser makes chips so small you cannot see them.

Top-down laser ablation works well for thin glass under 0.5mm with ps or fs lasers.

Bottom-up pulsed 532nm laser ablation with shorter pulses makes smaller chips, especially for thick glass over 0.5mm.

Laser cutting stops shaking and shocks that can harm glass. This way makes surfaces very smooth and helps create tricky shapes. New laser cutting tools also make work faster and waste less. This lowers costs for making optical glass parts.

Laser cutting makes fewer tiny cracks and defects.

The process gives smooth edges without extra work.

Better efficiency means big cost savings in optical glass cutting.

Tip: Laser cutting gives great precision and surface finish control for optical glass cutting. It is perfect for making many parts and for advanced uses.

Image Source: pexels

Chemical-mechanical polishing and bonnet polishing help make optical glass smoother. Chemical-mechanical polishing uses a pad and slurry to take away material. This works well for flat surfaces but has trouble with tricky shapes. Bonnet polishing uses a soft tool that bends to fit curved surfaces. It removes material fast and makes surfaces very accurate. Both ways help make more glass parts and keep quality high.

| Polishing Method | Throughput Impact | Yield Impact |

|---|---|---|

| Bonnet Polishing | Removes material quickly and fits curved lenses | Very accurate surfaces but can have odd effects |

| Chemical-Mechanical Polishing (CMP) | Only works on flat surfaces, not good for tricky shapes | Not good for odd or round shapes |

Bonnet polishing uses a flexible way to polish. It works well for curved lenses and is very fast. Chemical-mechanical polishing uses a big pad and mixes chemicals and rubbing. It helps make glass smoother but only works for open surfaces.

| Polishing Method | Characteristics | Limitations |

|---|---|---|

| Bonnet Polishing | Flexible tool, fast material removal | Can have strange effects like bending and relaxing |

| Chemical-Mechanical Polishing (CMP) | Uses big pad, mixes chemicals and rubbing | Only works for open surfaces, not good for odd shapes |

These polishing ways help control how smooth the glass gets. They make the glass better for making lots of parts. This means glass parts are smoother and more exact.

Bonnet polishing and chemical-mechanical polishing help make glass very smooth and improve how many good parts you get, but each way has its own problems.

Magnetic field-assisted batch polishing and multi-jet polishing are new ways to finish glass. Magnetic field-assisted batch polishing uses magnets to move tiny rough bits. It can polish many lenses at the same time. It makes glass very smooth and keeps the shape right. Multi-jet polishing uses streams of rough liquid to polish glass. Both ways make polishing faster and better.

| Technique | Process Time | Surface Roughness Improvement |

|---|---|---|

| MAF | 10 min (2−3 μm Rz to 0.1 μm Rz) | Big improvement |

| MMJP | 75 seconds (0.21 μm Ra to 0.04 μm Ra) | Very exact finish |

| MMJP | 40 seconds (0.32 μm Ra to 0.03 μm Ra) | Great surface quality |

Kang and team made glass smoother from 2−3 μm Rz to 0.1 μm Rz in 10 minutes using magnetic field-assisted batch polishing.

Wang and team made glass smoother from 0.21 μm Ra to 0.04 μm in 75 seconds with multi-jet polishing.

Yin and team got 0.03 μm roughness in just 40 seconds using multi-jet polishing.

Magnetic field-assisted batch polishing makes glass look like a mirror without hurting it. Magnets move the rough bits to polish glass gently. This makes glass super smooth and very exact. Multi-jet polishing also makes glass better very quickly. Scientists found that polishing longer can cause more problems. Using magnets helps the jets hit the right spot and stops them from spreading too much.

| Polishing Method | Advantages |

|---|---|

| Rotary Abrasive Fluid Multi-Jet Polishing | Makes glass smoother than old ways. |

| Ion Beam Figuring | Very exact and works with soft materials, gets super smooth glass. |

| Magnetorheological Finishing | Lets you control rubbing force, keeps glass safe and makes it very smooth. |

Magnetic field-assisted batch polishing and multi-jet polishing help make glass smoother and more exact. These ways help make lots of glass parts fast and keep the surface nice.

Magnetic field-assisted batch polishing and multi-jet polishing make glass smooth and finish fast.

Keeping tools and glass clean is important for polishing. Clean tools help make glass smoother and better. CVD diamond grinding tools can make glass very smooth. Fine CVD diamond wheels give a finish with roughness of Ra 5 nm. The way the tool wears down changes how smooth the glass gets.

Use air to blow away dust without hurting the glass.

Clean with soft cloths or lens tissues. Do not rub back and forth so you do not spread dirt.

Use safe cleaners like isopropyl alcohol. Pull dirt away instead of moving it around.

New polishing ways like rotary abrasive fluid multi-jet polishing and ion beam figuring help keep tools clean and last longer. These ways make glass very smooth and exact. Magnetorheological finishing uses magnets to make a soft tool. It makes glass super smooth and does not heat it up.

A control system in glass molding machines watches temperature, pressure, and speed. It changes settings while working. This keeps quality steady and stops mistakes when making lots of glass parts.

Airbag polishing changes air pressure to shape the glass. It helps remove material evenly and makes glass smoother.

Magnetorheological polishing uses magnets to make a soft tool. It makes glass very smooth and does not heat it up.

Watching in real time changes temperature and pressure.

Machines use sensors and smart programs to keep things just right.

Fewer mistakes mean better quality and smoother glass.

Keeping tools clean and watching for wear helps polishing work better. It keeps glass smooth and helps make lots of good parts.

Clean tools and new polishing ways help make glass very exact and keep the surface nice in optical glass polishing.

Recent studies show that UV-CMP and UEV-CMP polishing make glass smoother and faster to finish. The table below shows how these methods help:

| Polishing Method | Material | MRR Improvement | Surface Roughness Reduction | Additional Findings |

|---|---|---|---|---|

| UV-CMP | Copper-based | 90% | 40% | Works faster and makes surfaces better |

| UV-CMP | Sapphire | 60% | 25% | Makes a new soft chemical on the surface |

| UEV-CMP | Monocrystalline Silicon | 700 nm/min | 11 nm | Takes away the soft layer quickly |

| UV-CMP | SiC | 19.51% | N/A | Mixing ultrasonic and Fenton reaction helps speed up work |

Makers keep things exact by picking good materials, using smart machines, testing a lot, and checking quality often. In the future, there will be nanocoatings, green ways to work, more robots, 3D printing, new materials, and more ways to make special parts.

Surface finish changes how light moves in optics. Smooth surfaces help lenses work better. High surface quality makes optics more accurate. Ultra-smooth surfaces lower scattering. This gives clearer images and better efficiency.

Makers use special finishing and fast polishing. These ways remove tiny bumps and scratches. Magnetic-field-assisted polishing helps make surfaces smoother. Chemical-mechanical removal also helps. These steps improve accuracy and performance.

Accuracy helps optics focus light the right way. High-precision optics need exact surface texture. Good accuracy means optics work well. Ultra-smooth finish lowers errors. This gives better efficiency and longer life.

Profilometers and metrology tools check surface texture and accuracy. These tools scan the surface of optics. Makers use them to meet high quality rules. Accurate checks help control removal. This keeps surfaces ultra-smooth.

High-quality rapid polishing removes defects fast. This makes surfaces ultra-smooth. Makers save time and work more efficiently. Optics meet strict standards. Fast polishing helps make more high-precision optics.